Process Safety Beacon – Near-misses predict future incidents

A maintenance worker starts to unbolt a valve in compressed air service. Even though the line was reportedly depressurized, some pressure blew out. No injury occurred.

During rounds, an operator finds several sample points with the caps removed but there was no release.

These are two examples of near-misses; some companies call these near-hits.

Near-Miss

“An unplanned sequence of events that could have caused harm or loss if conditions were different or were allowed to progress but actually did not.” (CCPS Glossary)

The majority of operating companies report and investigate incidents. Many companies also collect near-miss reports. Although these are minor events, they are generally considered to be a good indicator of conditions that could ultimately lead to a severe incident.

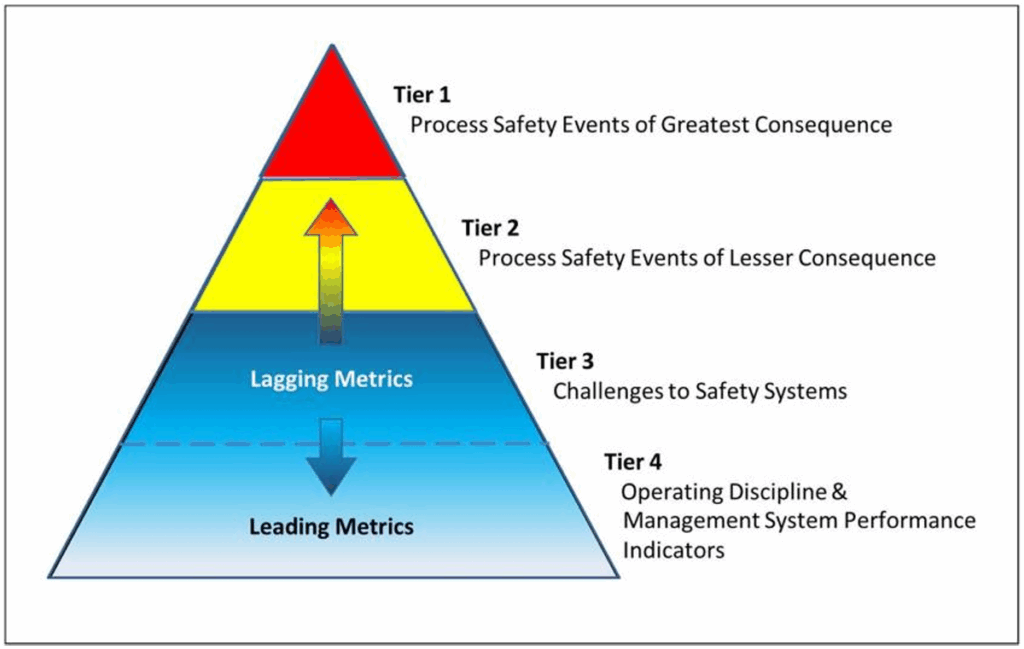

Near-misses are in Tier 3 of the metrics triangle shown in Figure 1. The full CCPS Process Safety Metrics Guide can be access at: https://www.aiche.org/sites/default/files/docs/page s/ccps_process_safety_metrics_-_v4.1.pdf

Did you know?

- Some other examples of near-misses are:

– Finding the operating procedure in use is not the latest version.

– A process instrument is found in poor physical condition or out of calibration.

– Noting missing information or data on field inspection reports.

– A pallet of raw materials that should be in the warehouse has been sitting on the dock for several days. - Near-misses indicate problems in one or more process safety systems. If these are not corrected, a more serious incident may occur in the future.

- Near-miss incidents may not require investigation, but they must be reported, collected and analyzed to reveal potentially serious trends.

- Companies have their definitions for near-misses and systems for reporting them.

- Not all near-misses occur in the field; they can be in the control room, maintenance shop or anywhere.

- An active near-miss reporting system is an indicator of a positive process safety culture.

- Many companies perform regular reviews of nearmisses to identify areas for improvement.

What can you do?

- Know your company’s definition of a near-misses (or near-hits) and how to report it.

- In your daily activities, watch for near-miss situations. There may be more of them than you thought.

- Report near-miss events to your supervisor.

- During safety meetings ask what has been learned from the near-misses system.

Report near-misses. Fixing minor issues may prevent a major incident !

Download the latest Process Safety Beacon

Source: AIChE 2026. All rights reserved.