Email Enquiry

Turkey Firefighter Injuries Wilst Testing

Foam System

Initial Email Enquiry –

At the request of the facility the details of the plant shall remain anonymous,

however, they were keen for the learning to be shared. My initial thoughts were

that it appears that the storz couplings used for the Hi-Vol were notf itted

with locking lugs (this to be confirmed) - which most fire brigades order as

standard. Also a permanently piped solution always is preferable to temporary

arrangements.

SUMMARY OF INCIDENT:

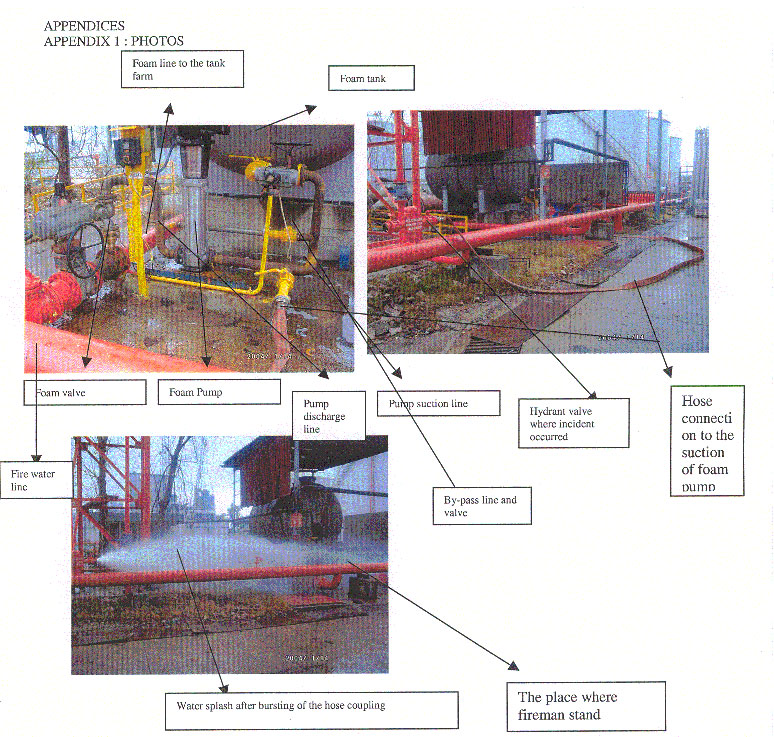

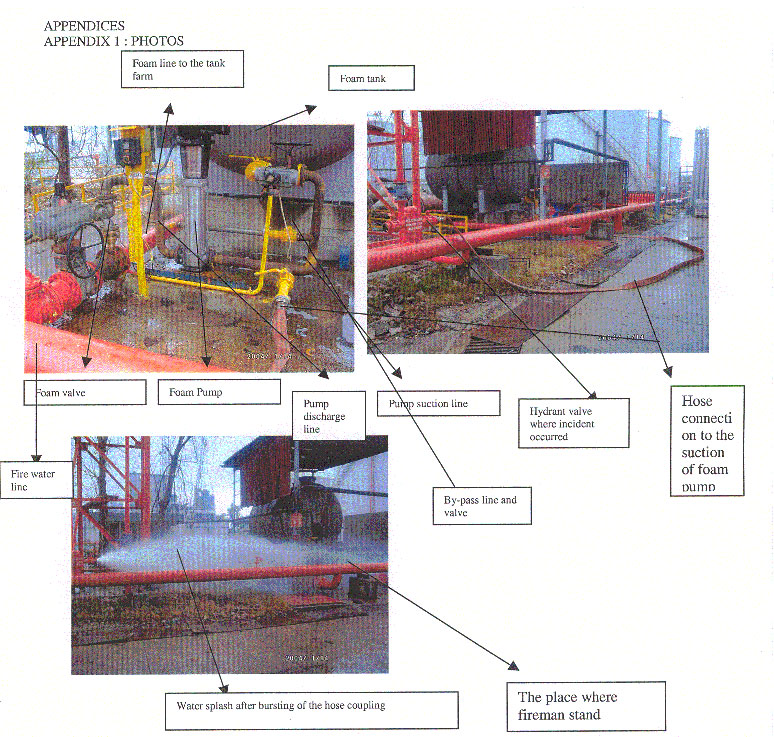

During flushing of the lines after testing of the automatic foam extinguishing

system of tank farm, storzs coupling connection of fire hose from a hydrant

valve to the suction of the foam pump burst and fire water at around 11 barg

hit to the fireman standing at about 5-6 m. Away from the hydrant valve on its

path . As the water jet hit the fireman, it caused him to fall backwards.

INJURIES TO PERSONNEL/DAMAGE TO PROPERTY/ENVIRONMENT:

The fireman hit back of his head to the support of foam pipes behind and had

a short cut on the scalp. He was taken to the infirmary first, got couple of

stitches and required medical treatment there. After his treatment, he was taken

to hospital for X-ray scanning. His examination by the shift medic in charge

revealed no fracture on his scull and neither any complications due to incident.

He was advised to call back to work by Medic in charge at the same shift.

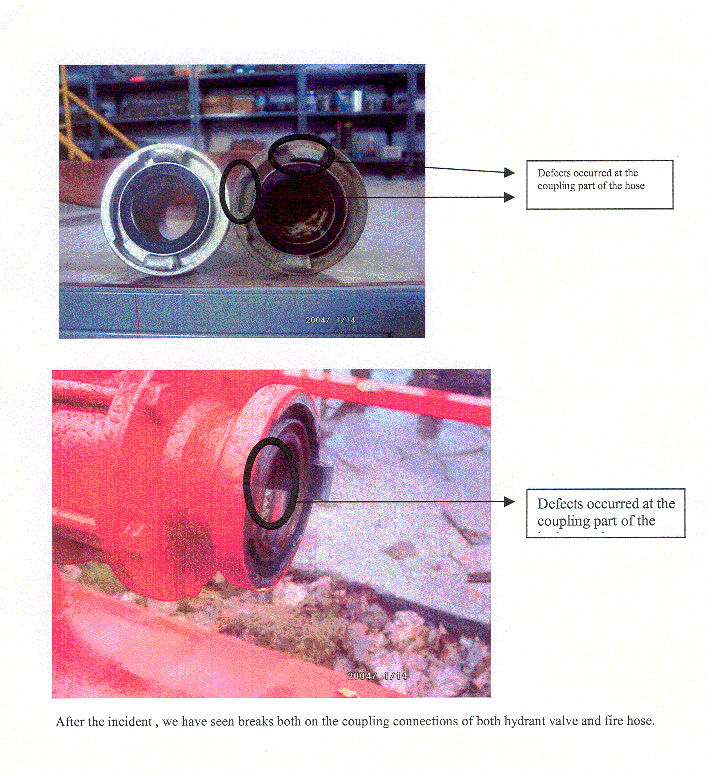

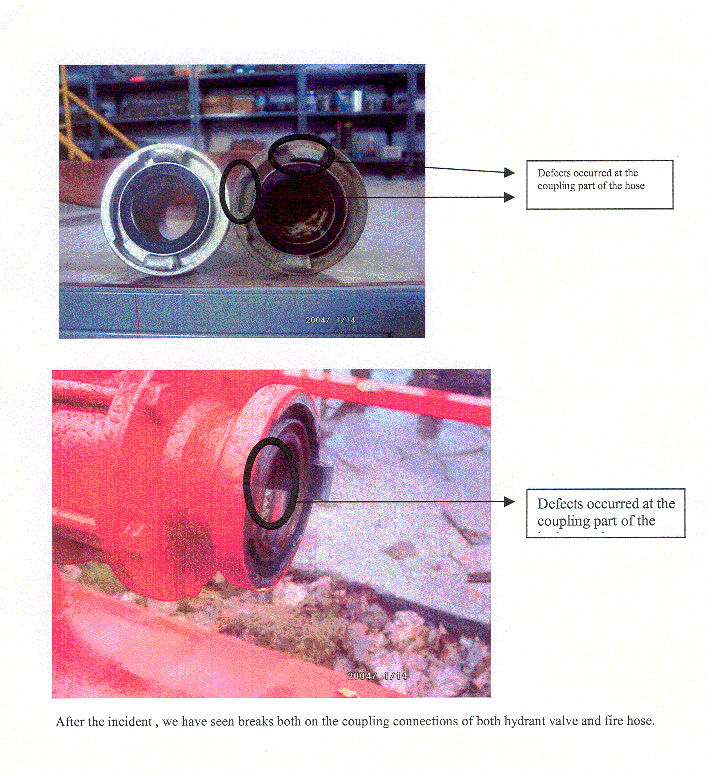

BASIC CAUSE:

Storz Coupling of the fire hose was damaged either from production or from the

use and it was believed that the coupling was not fixed properly to the hydrant

valve by the fireman. As the firemen opened the valve, since it was not fixed

properly, coupling slightly turned around loose half way and fractured which

caused the hose fly apart.

DESCRIPTION OF INCIDENT:

Foam pump and automatic foam concentrate ratio valve of the foam extinguishing

system of Tank Farm replaced because of corrosion after around 28 years of operation.

After installation of the new equipments, the system was tested. After the test

of the system by using foam, the lines should be flushed with water to clean

the lines not to cause corrosion in the lines, valves and the pump since the

foam solution is highly corrosive. So, a fire hose was connected to the nozzle

at the suction of the foam pump from a hydrant valve. Hydrant valve was opened

to feed water to the suction of the pump without running the pump and after

20-30 seconds the hose coupling at the hydrant valve was burst. The fire water

at around 11 barg from the hydrant valve jetted and hit to the fireman standing

at around 5-6m eter away from the hydrant valve on its course. As a result of

the hit caused by high pressure jetting water, the fireman fell down backwards

and hit back of his head to the pipe support behind him. He was sent to infirmary

immediately and treated there. He had a cut at back of his head and get couple

of stitches there. After this treatment he was taken to hospital for X-Ray and

further examination by a medic. Result of the examination showed no further

damage to his scalp and body other than the short cut on his scalp and he was

advised to call back to his duty.

DISCUSSION:

a) Operating Procedures and Site Practices: There was no updated procedure for

operation and testing of foam extinguishing system of tank farm.. So, necessary

procedure will be prepared and the responsibility of operation of the system

will bet ransferred to line management.

b) Quality Assurance : After the change of fire pump system, the line pressure

increased to 10-12 barg from 5-6 barg. So the importance of design and operating

pressure of fire protection equipment increased. The equipment that was bought

at the last 4y ears were proper to the pressure and all certified. But we have

now some old equipment that has no evidence of proper design pressure. So, all

the fire protection equipment at the site should be reviewed and necessary actions

should be taken.

c)Engineering Integrity: The fire hoses that are used for welding safety are

out of control of SHE Dept.They are not stored at the hose cabinets and are

open to defects during routine daily use at the plants. All the fire hoses at

the plants that were used for wildings will be collected, inspected and tested

at the SHE Dept. After inspections and tests, unsuitable ones will be be taken

out of use. The others will be labelled and will be returned back to the plants.

They will be collected and inspected quarterly by SHE Dept.

d) Training and Performance: Fire water pressure and the proper use of fire

protection equipment will be reminded to volunteer fire crew at the fire training

and exercise

IMMEDIATE CAUSE

1.There was defect either from the production or from the use at the coupling

of the fire hose.

2.Fire hose coupling was not fixed properly to the fire hydrant valve and coupling

slightly turned around loose half way and fractured which caused the hose fly

apart.

RECOMMENDATIONS

- A temporary fire hose connection for flushing of foam lines will be cancelled

and a temporary line will bei nstalled

- All the fire hoses at the plants that were used for wildings will be collected

, inspected and tested at the SHE Dept. After inspections and tests, unsuitable

ones will be taken out of use. The others will be labelled and will be returned

back to the plants. They will be collected and inspected quarterly by SHE

Dept.

- There will be an announcement to remind the people not to use fire water

for the purposes beside fire and welding safety. At the same time it will

be also reminded to use the labelled fire hoses for the welding safety instead

of the ones that will be used in case of a fire ONLY

- All the hydrant valves at the site will be reviewed and the ones that are

not serving properly will be corrected. Also the non-standard hydrant valves

and couplings at these valves will be replaced

- All the hydrants at the site will be reviewed and missing hose and hose

cabinets will be installed

- The operating and test procedure for foam extinguishing system of Tank farm

will be reviewed and revised and operating responsibility will be transferred

to Line Management

- All the fire hose cabinets will be reviewed and hose couplings will be inspected

for defects.D efected ones will be taken out of use

- Fire water pressure and the proper use of fire protection equipment will

be reminded to Volunteer fire crew at the fire training

1st Response –

This may be one of the reasons that the NFPA put together a new standard on

hose couplings and fittings. I have always thought that there was more of these

that we knew about.

There is people in our business that have a problem with uncoated aluminum

fittings and couplings. Much of the water that is used in our plants for fire

water is untreated and can cause corrosion on fittings such as aluminum.

It may be that only time will tell. Remember that we have only been using

these aluminum stortz couplings in industry in large quantities for 10-15 years

at the most.

End of email correspondence on Topic to date.

Author’s identities are concealed for privacy and

security reasons. Further information on the information contained in this topic

can be directed to the JOIFF secretariaty. |