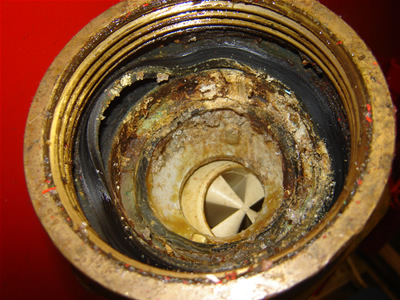

Incident Report Subject: Gasket Deformation - Your Views Date of Email reporting Incident: Sun 04/06/2006 20:00 Report Detail: During an inspection of a client's vessel (cruise ship), an individual from their corporate office commented that he thought the visible deformation of the gaskets in the vessel's fire fighting nozzles was caused by contact with the generous amount of petroleum based lubricant (grease) applied to the threads on the appliances and fire hose (see attached photo). Can you supply any input concerning the validity of this theory?

Responses:

|