CHINA - ALCOHOL PLANT FIRE IN HEFEI INJURES SEVEN

Firefighters race to extinguish an alcohol plant fire in Hefei, Anhui

Province April 25, 2005. The fire started at about 19:00 on Monday, and

several explosions occurred during the fire. At least seven people were

rushed to local hospitals for injuryt reatment. Several thousands residents

nearby were evacuated for safety consideration. The fire was put out about

three hours later and the cause is under investigation. residents nearby

evacuated for safety consideration

View / download full story here

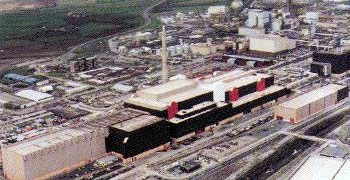

CANADA - INSURERS COULD FACE $IB PAYOUT FOR DISABLED SUNCOR OIL

SANDS PLANT, OSFI SAYS

An estimated $1-billion insured loss at Suncor's disabled oil sands facility

in northern Alberta could put a strain on some Canadian insurance companies,

the Office of the Superintendent of Financial Institutions says.

A letter to Canada's insurance industries, dated May 4 and posted Wednesday

on OSFI's website, said a signifiant portion of the financial exposure

from a Jan. 4 fire will be borne by Canadian federally registered re-insurers.

"While the ultimate cost of this loss is yet to be finalized, the significance

of requirements the loss was well known to the industry in early 2005,"

OSFI assistant superintendant wrote in the letter. The magnitude of the

insured loss may "severely stress" individual companies' capital adequacy

positions, he said. However, the OSFI assistant superintendant added that

OSFI has committed to allow some flexibility with respect to target levels

to allow institutions to absorb unexpected losses and to allow for other

temporary declines below the supervisory target level, he writes. "Accordingly,

where institutions have demonstrated good capital management, a short-termb

reach of capital targets from this event will not result in an automatics

taging action. We would expect however, that any resulting capital shortfalls,

upon discovery, will have been corrected without delay," the OSFI assistant

superintendant concludes.

Calgary-based Suncor Energy said last week that it expects its oilsands

upgrading refinery in northern Alberta, which has been working at about

half capacity since a January fire, will return to full operations in

September. The fire was a key contributor to the 55 per cent slide in

Calgary-based Suncor's first quarter profits to $98 million, down from

$216 million in 2004 despite near-record global oil prices.

Suncor also said the company expects its insurance policies to cover

much of the costs. Suncor chief executive told shareholders on April 28

that the cost of repairs, excluding a$ 10-million US deductible, the damage

would be covered by the company's $250-million US insurance policy. In

addition, Suncor has a $200-million US insurance policy to cover business

interruptions that has a $50-million US deductible. And there is another

$700-million US policy that can be used for damages or business interruptions.

Suncor chief executive said a final bill for the fire won't be known

until more of the repair work is completed. The damaged portions of the

upgrader are currently about 20 per cent re-built. The Jan. 4 fire was

confined to one of Suncor's two coker fractionators - a large vessel that

separates the various crude products that come out of the oily mud shipped

from the oilsands. According to the Suncor chief executive, one pipe at

the bottom of the tower had the wrong steel specifications, causing it

to erode faster than expected. The fire burned for nine hours and water

damage from extinguishing the blaze was severe, although no one was hurt.

USA - FIREFIGHTERS QUELL LONG BEACH REFINERY BLAZE

LONG BEACH

An oil refinery at 2400 E. Artesia Blvd. in North Long Beach caught fire

early Sunday morning, possibly after seals in a pipeline failed, firefighters

said.

Though still under investigation, the 3:32 a.m. fire at Edgington Oil

Refinery appears to have originated in an 8-inch, above-ground pipe carrying

heavy crude oil, said Fire Captain of the Long Beach Fire Department.

Oil leaking from the pipes fueled 30-foot flames and a 200-foot smoke

column. The Capt. called it "a big fireball." More than 50 firefighters

from the LBFD and Los Angeles County Fire Department responded to the

two-alarm fire, which was under control by 5:30 a.m.

Crews from the Long Beach Health Department assisted with the cleanup.

No one was injured, but the firefighters will likely have to replace their

protective clothing, or "turnouts." "They were covered

from head to toe with oil," the Fire Captain said.

In a separate fire at 11:19 p.m. Saturday, firefighters were dispatched

to an apartment above a garage at 519 E. Hill St. No one was hurt, but

one of the units in the two-unit complex was deemed uninhabitable, the

Fire Captain said. The Red Cross, he said, would assist the occupants

a woman in her 30s and her 4-year-old daughter with housing. The residents

were not home at the time of the fire. The cause is under investigation.

USA - SMALL REFINERY FIRE QUICKLY CONTAINED

A fire at Tesoro Alaska's Nikiski oil refinery left one production unit

that produces jet fuel shut down. The unit will be down for an unknown

period of time, said vice president of refining for Tesoro. The fire was

small and happened in an isolated area, the vice president said, adding

there were no injuries and that it was not necessary to evacuate employees.

There was no significant damage to the plant, he said.

The vice president of refining said the cause of the fire is unknown.

The refinery has about 178 employees. The fire occurred just after 11

a.m. Tesoro's fire brigade and the Nikiski Fire Department responded to

the fire. The fire department responded with five units and 17 firefighters.

No flames were showing when the fire department arrived, said assistant

fire chief for the department.

Tesoro's Nikiski refinery is capable of producing up to 70,000 barrels

per day of crude oil. Jet fuel, diesel and gasoline are produced at the

refinery. Hansen said about 65,000 barrels per day of crude oil were produced

Thursday. There are 149 oil refineries in the United States, six of them

in Alaska, according to the Energy Information Administration. Tesoro's

refinery is the second largest in the state. The refining industry has

a better safety record than other manufacturing operations, said an economist

for the American Petroleum Institute.

The assistant Chief said firefighters with the department have additional

training in fuel spills and hazardous fires because of the four industrial

plants in the community. Responding to fires at these facilities is second

nature, he said. Each of the Nikiski plants has its own fire units. The

fire department acts as backup to these fire brigades, he said.

View full story here

TUNISIA - OIL ENGINEER DIES AFTER TANKER FIRE

A British oil engineer has died after a fire on board a tanker off Tunisia,

the Foreign Office said tonight. The victim drowned after the crew were

forced to abandon ship as the blaze took hold. He dived into the water

but was unable to reach the shore or a lifeboat and his body was recovered

24 hours later. It happened last Friday 1.2 miles off the island of Kerkennah.

Tunisian authorities are investigating. The fire broke out in the engine

room of the tanker. Two Tunisians also drowned in the accident. Six people

were rescued. The Foreign Office said no other Britons were involved.

The victim originally thought to be from London, was married and had

been living in Tunisia for some years. He was working on an oil pipeline

for Mondial Contractors. A Foreign Office spokesman said: "His company

are liaising with the next of kin. We have offered consular assistance.

“The investigation into the circumstances surrounding the accident is

obviously a matter for the Tunisian authorities."

UK - WORKER KILLED, EXCLUSION ZONE AT PLASTICS FACTORY

An exclusion zone has been set up around a plastics factory where an

explosion killed one man and injured five others.

The blast happened last Friday at James G Carrick & Co plastics and

metal plant in Glasgow's Springburn area. A 60-metre perimeter fence has

been erected while the building is checked and machines similar to the

one that exploded are being examined.

A police spokeswoman said the machines could still pose a safety risk.

She said: "The initial investigation of the site revealed that a

machine within the factory had given rise to the explosion. "Similar

machines need to be examined and while remote, there is a possibility

that other plant and machinery in the factory may give rise to a risk.

"A precautionary exclusion zone will be set up around the factory,

including an adjacent business and playing fields, to secure the site

and keep the public away."

Experts from the Royal Logistics Corp EOD Bomb Disposal Unit will examine

and make safe the plant and machinery by remote means. The spokeswoman

said there was no danger to the public and said the measures were being

taken to ensure the safety of inquiry personnel during the onsite investigation

process. She added: "There is no question of any explosive material

having been manufactured or stored at the premises. "This was an

industrial explosion." This stage of the investigation, involving

police, the Crown Office, procurator fiscal and health and safety executive,

should be completed by Friday evening.

A factory worker died in hospital on Tuesday after he was seriously injured

in the blast. A second man remains in a serious but stable condition in

hospital. Four others received treatment for minor injuries at Stobhill

Hospital. The explosion came nearly a year after Stockline Plastics in

the city's Maryhill collapsed, killing nine people and injuring dozens

more.

NORWAY - GAS ALARM HALTS PRODUCITON AT OSEBERG C

A gas alarm halted production for a few hours Monday aboard the 70,000

barrel-per-day Oseberg C offshore platform, sending crew members into

lifeboats as they prepared to evacuate, Norsk Hydro ASA said.

The leak aboard the North Sea platform was quickly repaired, and production

resumed later with no damage or injuries, the company said. As a precaution,

most of the platform crew of 68 people entered lifeboats and were ready

to evacuate the platform, some 130 kilometers (80 miles) northwest of

Bergen, Norway's second-largest city, the company said.

If ignited, a gas leak can cause an explosive fire and endanger a platform

and crew. Inger Anda, spokeswoman for the Norwegian Petroleum Safety Authority,

said the state agency was following developments on Oseberg C closely.

"We still have very little information about it. That could take

a few days," she said by telephone. She said the authority was in

regular contact with Hydro about the leak, and expected a full report

when the company completes its own investigation.

Norsk Hydro said the leak was detected at 00:35 local time (2235 GMT

Sunday). Repairs were completed and the all-clear sounded 40 minutes later,

with production returning to normal levels during the morning. The leak

was traced to a valve gasket in the platform's drilling systems. Norway

is the world's third-largest oil exporter, after Saudi Arabia and Russia,

with a production capacity of about 3.2 million barrels per day of oil

plus vast flows of natural gas.

USA - MASSIVE EXPLOSION ROCKS A BOLIVAR PROPANE BUSINESS

The public was kept at bay, nearly two miles away, while emergency crews

kept watch Friday afternoon. But the flames were clearly visible from

Chopper 5's vantage point.

"This gentleman has lost his entire business," said Hardeman

Co. EMA Director. The business was called Dixie Gas, located off highway

125 just south of Bolivar.

Officials say Friday's emergency began as a gas leak. "As soon as

we showed up, it was an explosion," said Bolivar Fire Chief. Hundreds

of small propane tanks, like those used to fuel bar-be-que grills, blew

up. After that, all eyes were on a series of much larger containers. "Got

seven six thousand gallon propane tanks all piped together which caught

fire," said the Fire Chief.

It was quickly determined that even with seven departments on the scene,

fighting this fire was futile. "And we're kind of letting nature

take its course right now, we want it to burn itself out," said the

Fire Chief. So they sat all afternoon and into the night.

Meanwhile, nearby residents were moved out. They were ordered to leave

their homes until the threat was over. "Say a mile to a mile and

a half in every direction," said the Fire Chief. Most people should

be back at home by Saturday afternoon. That's when the extent of the damage

will be assessed. But for now, people in this small town are glad this

big news didn't do more damage.

There is an environmental component to this emergency as well. A creek

runs alongside what's left of that propane business. State officials are

on the scene to help determine if any contamination has occurred.

INDIA - WORKDRE SUSTAINS 80% BURNS AS SOLVENT CATCHES FIRE

A 54 year old worker of the Alembic Pharmaceuticals was severely injured

while working at the factory on Sunday afternoon.

He was later admitted to the SSG hospital with 80 per cent burns. The

victim, had reported for duty in the first shift at Alembic’s ATI-14

production plant. ‘‘The victim along with another person were

handling some solvent required for making a product Cepa 5. He was injured

while the solvent caught fire owing to a static charge. The fire was not

major and our in-house fire fighting team controlled it in no time,’’

said Alembic spokesperson. The victim was admitted to to SSG hospital

owing to seriousness of his injuries, said the second victim. Though no

police complaint have been registered yet, Gorwa police officials say

they are looking into the matter.

UK - RADIOACTIVE LEAK SHUTS DOWN UK NUCLEAR REPROCESSING PLANT

Members of the European Parliament are demanding that the United Kingdom

government launch an immediate independent inquiry into the situation

at the UK's Thermal Oxide Reprocessing Plant (THORP) facility at Sellafield

in Cumbria.

The nuclear fuel reprocessing facility was closed down April 20 following

a leak of radioactive fuel. About 20 metric tons of plutonium and uranium

fuel dissolved in nitric acid leaked from a cracked pipe into an enormous

secondary container that is too radioactive for workers to enter. Officials

say specialized robots may have to be built to clean up the spill. Plant

managers maintain that no radioactive material has escaped into the environment,

although the exact details of the incident remain closely guarded.

The European Commission has not received any information about the circumstances

of the leak. A Green MEP said the accident highlights the daily health,

security and environmental risks of the nuclear power industry. “The

reprocessing of spent fuel is just one aspect of an industry that is dangerous,

dirty and expensive,” said the Green MP, who represents South-East

England and is a member of the European Parliament’s Environment

Committee. The Chairman of the Nuclear Decommissioning Authority which

took over ownership of the plant from British Nuclear Fuels on April 1,

said, “Our first priority is always safety, and we have been reassured

that there is no immediate concern on that front."

The THORP facility was transferred to the Nuclear Decommissioning Authority

as part of a reorganization of the UK’s £40 billion nuclear

waste liabilities. But the European Commission is investigating the transfer

under rules governing illegal state aid, and THORP’s future is uncertain.

The facility is designed to separate plutonium from spent nuclear fuel

for customers from various countries, though it has been beset by problems

and has never functioned at full capacity. The Nuclear Decommissioning

Authority is tasked with cleaning up the UK's nuclear legacy, but the

THORP accident has slowed that process because its contribution to the

cleanup budget will not be available as long as it is shut down. “This

year’s budget of £2.2 billion is likely to take a hit but

it is too early to be absolutely clear by how much and consequently how

we will manage the impact and the consequences for the future of the plant,"

chairman of the Nuclear Decommissioning Authority said. About £560m

of the budget total was to come from the THORP plant.

The Nuclear Decommissioning Authority’s director of nuclear safety

and security, is an observer on the Board of Inquiry set up by British

Nuclear Group to carry out a detailed investigation into the incident.

But that investigation does not satisfy Members of the European Green

Party. They want an independent examination of the spill. German Green

MEP said, “The European Commission and the UK government must immediately

launch an independent inquiry into both the causes and the consequences

of the accident. Considering the inherent risks and the absence of any

economic future of the plutonium industry, these plants in both the UK

and in France should be abandoned.”

The spill casts a shadow of doubt on the current labour government's

renewed interest in building nuclear power plants. The government has

always said it is right to “keep the nuclear option open”

along with the drive to boost renewable energy sources, the government's

chief scientist said Tuesday. He was speaking before a two day G8 Energy

Research and Innovation Workshop at Oxford University that opens today.

On the other hand, some have warned that the UK faces electricity and

gas shortages, leading to steep price increases, unless action is taken

to replace the UK's aging nuclear plants. The Green MEP said, “The

current Prime Minister has raised the spectre of building new nuclear

power stations as a way of meeting the UK’s international legal

obligations to reduce CO2 emissions. Not only is this misguided - as this

accident has amply demonstrated - it is based on a fallacious assumption

that nuclear energy is carbon free." “The reality is that over

its full life cycle a nuclear power plant is responsible for significant

CO2 emissions," the Green MEP said. "If he is serious about

safely reducing greenhouse gas emissions, The British Prime Minister must

abandon the dirty and dangerous nuclear power industry in favor of renewable

sources such as wind, wave and solar power - and invest heavily in energy

conservation measures,” she said. “This incident has served

to close the plant for the foreseeable future - the government must take

the next step and keep it closed for good," said the Green MEP. "The

government shouldn’t even be talking about commissioning new nuclear

plants while we remain stuck with the mess of the last 50 years,”

she said. "The deadly by-products of the nuclear energy industry

must in no way be used as a raw material for new industrial processes,"

said the Green MEP.

A decision on whether or not to build a new generation of nuclear power

plants is among the most controversial which the British Prime Minister

faces at the start of his third term.

UK - WORKERS TREATED IN HOSPITAL AFTER ACID GAS LEAK AT FACTORY

Five workers had to be treated in hospital after an acid gas leak at

a pharmaceutical factory in the Capital. They suffered breathing problems

and irritated eyes after hydrochloric acid escaped from containers at

MacFarlan Smith’s in Wheatfield Road, Gorgie. Seven more workers

were treated with oxygen by paramedics at the scene.

A health and safety investigation was today launched to find out what

caused the leak. Seven fire appliances were called to the scene and 27

firefighters wearing protective clothing and breathing apparatus spent

almost two hours making sure the site was safe.

Staff were evacuated by the factory’s own fire team after a cloud

of the gas was spotted in a building on the factory’s east side

at 11pm last night. The leak was traced to three kilograms of hydrochloric

acid in gas form, which is used as part of the drug-making process. A

site engineer managed to isolate the leak by shutting down the surrounding

area and getting staff out of the building.

A spokeswoman for the firm said today around 20 members of staff were

evacuated. "Workers were carrying out a routine process on the east

side of the plant. "The process required a small amount of hydrogen

chloride gas to be used to form a salt. "During this process, a small

quantity of gas was vented which was released into the atmosphere. At

that point, the site was evacuated and the gas cloud dissipated after

eight to ten minutes." The injured workers had initially been walking

around normally after breathing in the gas, but quickly developed side

effects. The five taken to hospital were later released.

The leak was reported to the Scottish Environment Protection Agency and

the Health and Safety Executive. A spokeswoman said: "Sepa will be

inspecting the site as a result of this minor incident to confirm the

cause and agree any improvement to prevent such an incident occurring

in the future." Staff arrived as normal for the day shift this morning.

The company spokeswoman said the Sepa investigators were "satisfied"

that the gas had safely dissipated into the atmosphere and posed no threat

to the public. Edinburgh-based MacFarlan Smith is a Johnson Mathie business

and is one of the country's largest manufacturers of diamorphine. The

company is Britain’s only licensed opium processor, and supplies

both Chiron and Wockhardt UK with an unrefined version of the drug.

Sighthill fire station officer was one of the first on the scene last

night. He said that while fire crews ended up being there as a precautionary

measure, the incident could have been much more serious. "It is a

very dangerous acid, and we had to treat it in that respect when we were

at the scene," he added. "We had to look at weather conditions

and the time lapse since the leak to determine the situation, which potentially

could have been a big problem." Four of the fire appliances were

ordinary tenders, while three carried specialist equipment worn by fire

crews dealing with dangerous chemical leaks.

View full story Here

USA - RESIDENTS FUMING OVER HUNTSMAN LEAK

A recent pipeline rupture near Port Arthur's El Vista area has neighborhood

residents fuming mad over how the potentially dangerous situation was

handled. When a Huntsman Refinery pipeline began leaking propylene and

propane into Alligator Bayou early Friday morning, El Vista residents

said they were provided with little to no information regarding the leak.

While Port Arthur fire marshals blocked traffic from Savannah Street

to Texas 73 Friday, the officers did not alert anyone as to what exactly

was going on near their neighborhood, an eye witness El Vista resident

of almost 30 years, said. "When trying to go toward Savannah, people

were just told to go back, but no one would tell people what was going

on," the eyewitness resident said.

Port Arthur emergency officials and hazardous materials authorities

issued an "In Shelter" emergency message to notify area residents

of the incident, and to ask them to remain inside their homes with air

conditioners and window fans turned off. But many El Vista residents said

they never received the message and had no clue what an "In Shelter"

emergency was. Another eyewitness El Vista resident of more than 47 years,

said she learned of the warning from a neighbor, but that she did stay

in the house for the rest of the day. "A little boy down the street

came and told me about the warning," she said. "So, I went ahead

and turned off the air conditioner and stayed indoors." The first

resident said a neighbor told him about the warning as well. "A neighbor

had to tell me about the warning and I didn't know what it meant,"

he said. Instead of staying indoors, the resident said he got in his car

and drove to Beaumont to stay with a relative for a few hours. "The

only way I knew about the all-clear was because I called a neighbor,"

he said. "There just wasn't enough information given to residents.

There wasn't enough communication."

With almost all on-duty fire officials handling traffic and monitoring

air quality near the El Vista area during the pipeline leak, PAFD Deputy

Fire Chief said there was hardly any personnel left to knock on neighborhood

doors to alert El Vista residents of the "In Shelter" message.

"Its just not physically possible for us to have people knocking

on every door to tell residents to stay in the house," the Fire Chief

said. "We just attempt to use what method we can to alert them."

The Fire Chief said emergency officials use the Southeast Texas Alerting

System, (STAN), to alert the community of environmental emergencies. Police

dispatchers notify the local media and then, televised and radio broadcast

warnings are issued. "The problem was that very few people were watching

their televisions," the Fire Chief said.

Huntsman officials met with El Vista residents recently to discuss the

concerns of neighborhood citizens, the Fire Chief noted. During the meeting

with Huntsman authorities, The first eyewitness resident said El Vista

residents talked with the refinery officials regarding new and innovative

ways to alert residents of potential environmental emergencies.

A Huntsman Corporation Spokesman said the meeting with El Vista residents

was very positive and the corporation is looking into better ways to alert

the community when emergencies take place. "When you do have an "In

Shelter" warning, you want to make sure everyone knows about it,"

the Huntsman Corportation Spokesman said. "We are definitely looking

into finding out how to do a better job to make sure everyone gets the

message."

AUSTRALIA - PLASTICS FACTORY FIRE PROMPTS HEALTH CONCERNS

Residents in the western Adelaide suburb of Findon are being urged to

stay indoors and to lock windows as acrid smoke from a fire in a plastics

factory could cause health problems. Police are investigating the cause

of a $4 million fire. Fourteen fire appliances and 50 firefighters were

called to the Exacto plastics factory in Alfred Street, Beverley, after

a blaze broke out about 2:30am ACST.

Police say workers were inside the factory, however it is not known how

the fire started. At the height of the fire, black acrid smoke filled

the air and people nearby were advised to stay indoors. Buildings and

stores of plastics used for car parts were destroyed. It took firefighters

an hour to bring the blaze under control. Crews remain on the scene as

the melted plastic and the building are still smouldering.

View full story here

USA - 50 SICK AFTER CHEMICAL TRUCK CRASH

A truck carrying barrels of a chemical crashed and burst into flames,

killing the driver and sickening nearly 50 emergency workers who were

exposed to the fumes. The tractor-trailer crashed at about 11:50 p.m.

Thursday on a four-lane highway. The highway remained closed in both directions

Friday morning."It appears the truck's brakes caught on fire and

caused the trucker to lose his brakes as the truck was coming off the

grade," said Deputy of the Mingo County Sheriff's Department said

Friday.

The truck was carrying barrels of a polyurethane-based liquid called

RePneu II, which is used to fill the tires of off-road coal mining and

construction equipment to prevent flats, Mingo County Emergency Services

said.

Firefighters responding to the accident initially thought the leaking

liquid was oil, but they began complaining of breathing problems and other

ailments. They were taken to Williamson Memorial Hospital for decontamination

and treatment for eye and skin irritation. "It was hard to breathe,"

said Deputy of the Mingo County Sheriff's Department, who was among those

seeking treatment. "When I first arrived on scene it was just a fireball,

pretty much, a smoky big mess."

View full story here

RUSSIA - SHIPYARD BLAZE KILLS FIREMAN, DAMAGES CHINESE DESTROYER

One firefighter has been killed in a blaze that struck a missile destroyer

under construction at a shipyard in St. Petersburg. Another fireman has

been injured, the Interfax news agency reported citing St. Petersburg

emergency officials.

Preliminary reports said the blaze had triggered an explosion on board

killing one person. Another fireman was hospitalized with injuries, the

regional directorate for the Emergencies Ministry told Interfax. The fire

broke out around 09-00 on Wednesday. By 12-00 it had been contained, a

spokesperson for the ministry told Interfax. Four people were rescued

from the burning vessel.

According to unofficial reports, the fire broke out on board a missile

destroyer under construction at the Severnaya Verf shipyard ordered by

the Chinese navy, a source in defense industry told Interfax in Moscow.

“The fire at the shipyard took place on board one of the two destroyers

under construction for China,” the agency’s source said. However,

no official information either confirming or refuting his statement was

available, the agency said. The ministry spokesman told Interfax that

the ship affected has a displacement of 8,000 tons.

The Emergencies Ministry said the ship had been nearing completion. Russia’s

arms trading concern Rosoboronexport signed a $1.4 billion deal to deliver

new-generation 956EM missile destroyers to China in 2005-2006. The 956EM

destroyers will boast cutting-edge armament assets. This vessel has been

designed to counter hostile surface ships and landing craft, countering

anti-aircraft and anti-missile defenses of combat and transportation ships,

providing fire support to landing units, and patrolling and carrying out

various missions as part of a formation or separately. The 956EM destroyer

is fitted with advanced missile and artillery assets and torpedo, radar

and anti-submarine systems, as well as the Moskit supersonic anti-ship

cruise missiles. The destroyer is 150 meters long, and is capable of traveling

at a speed of 34 knots (60 km per hour). |