CALTEX TAKES PRECAUTIONS AFTER BLAZE

The Caltex Refinery in Milnerton is to be shut for at least two weeks

following a fire in one of its pumps on Friday and major customers' fuel

supplies are to be rationed as a "precautionary measure". The

refinery's manager said on Sunday that most of the refinery had been shut

down so the damage could be assessed. "We will be down for at least

two weeks while we look at the damage," said the manager. "Until

we do the initial assessment we don't have a feel of the damage and the

cost. "As a precaution, we are going to do rations of all our biggest

customers to make sure we don't have a supply problem. This is the responsible

thing to do." The refinery's public affairs manager said although

product supply was not expected to be affected, as a precaution the company

would develop contingency plans until the extent of the repairs needed

was known.

The fire broke out about 6.40pm on Friday and was extinguished by 8pm

by the refinery's emergency service teams, assisted by the Milnerton fire

station. The refinery manager said an investigation into the cause had

been launched. "When anything goes wrong I launch an investigation

to find out what the problem was. "We treat it like a forensic investigation.

We are doing everything we can to prevent incidents." Refinery staff

had met officials of the department of environmental affairs and tourism,

the department of environment and development planning and the City of

Cape Town's air pollution control to provide them with an understanding

of the incident. The police and department of water affairs and forestry

also visited the site. "Today contractors will come in to do the

assessment," said the refinery manager. "We also do turn-arounds

every year to tune things up. This is one of the safest refineries in

South Africa and we make sure there are no injuries."

Residential areas flanking it have been concerned about the refinery's

safety following a number of incidents. The fire was the fourth incident

this year. Last year, during a routine annual shut-down of the refinery

for maintenance, oil rained on neighbouring houses and cars. The Democratic

Alliance has called on the department of minerals and energy to ensure

the refinery's management undertakes a thorough investigation of the fire.

The DA spokesperson on minerals and energy, said the fire broke out hours

after members of the portfolio committee on minerals and energy and select

committee on foreign affairs visited the refinery. "It appears from

information gathered during our visit that the steps taken by Caltex to

make the refinery safer are inadequate," said the spokesperson.

FF's INJURED WHEN APPROACHING CAR FIRES

There has been another strut incident at a car fire. A Sacramento, CA

Metro firefighter was very lucky in January after a super-heated strut

under the hood of car on fire exploded, sending the 1" cylinder through

the vehicle's body and right through his leg before "landing"

more than 50' away. "I moved to the passenger side of the vehicle

and started to extinguish the fire through the front grill when all of

a sudden, we heard a large explosion," said the firefighter. The

strut was so hot it actually cauterized the firefighter's wound, just

missing the victim's femur before exited through the back of his leg.

The firefighter is recovering and expects to be back at work next week.

Similar situations have occurred to other FD's as well...one specifically

in CT several months ago that is covered in the current issue of Firehouse

Magazine, "Close Calls" Column, Pg 26. As we wrote, it's JUST

a car fire-one where our risk should be minimal when we cautiously approach

in/from a safe area w/full PPE and a charged & flowing line to cool

& reduce the temps of the vehicle/strut areas.

A Windspr Locks Firefighter was hospitalized after suffering a leg injury

while fighting a car fire on Nov 21st. While attempting to open the hood

latch one of the hood struts exploded sending the strut completely through

the firefighter's upper thigh. The firefighter is home recovering from

his injury.

GAS EXPLOSION KILLS FIREFIGHTER, INJURES THREE OTHERS, IN NORTHWEST ITALY

A firefighter was killed and at least three others were injured in an

explosion triggered by a gas leak Wednesday in this northwestern port

city, fire officials said.

A leak in a tanker truck first ignited a fire, they said. When firefighters

arrived to battle the blaze, they were hit by the explosion, they said.

Firefighters said details were still unclear. The Italian news agency

ANSA said that as many as 10 people were wounded, but that report could

not immediately be confirmed.

View full story here

WORKER DIES ON NORTH SEA PLATFORM

A man has died on a North Sea oil platform off the coast of Shetland.

Electrician Graeme Burns, 47, died while carrying out maintenance work

with a colleague on Brent Bravo on New Year's Day. The pair were in a

leg when they smelled gas at 0230 GMT. The victim, from Largs, who worked

for the John Wood Group, collapsed and died. An inquiry has begun into

his death on the platform, which is 116 miles north-east of Lerwick. Its

owner, Shell, said it was investigating the death with Grampian Police

and the Health and Safety Executive.

Gas detectors

The company said the smell the men detected may have been a naturally

occurring gas and it did not believe there had been a leak in the platform

leg. A spokesman said: "The victim and a colleague were working in

the utility shaft when they smelled a minor amount of gas. "One of

their portable gas detectors registered the presence of gas but none of

the 11 gas detectors in the shaft registered gas. "They donned breathing

equipment and began to evacuate the shaft. For some reason yet to be determined,

the victim stopped climbing the stairs of the shaft. "He was later

found unconscious. Medical assistance was applied but unfortunately he

was pronounced dead. Our sympathy goes out to his family and colleagues."

Previous deaths

In September 2003, 2 oil workers died after a sudden escape of gas when

they were working inside the same utility shaft. A Grampian Police spokesman

said: "We can confirm that we have officers at Brent Bravo making

inquiries into the death of a crew member on that installation. "Obviously

it is too early to speculate on the circumstances surrounding the death."

View full story here

NEW ZEALAND, RICHMOND, JANUARY 28 2005. FIRE IN OIL TANK CAUSES 'SPECTACULAR FLAMES'

A fire in an oil tank containing thousands of litres of oil broke out

at Nelson Pine Industries' MDF plant in Richmond this morning. Richmond

Volunteer Fire Brigade chief fire officer said the fire started around

3.30am sending thick black smoke billowing over Tasman Bay.

Fire fighters initially feared the fire was bigger than it was, as burning

oil from the tank was venting through a furnace next to the tank, and

causing "spectacular flames" to leap outof the furnace. There

was also concern at the potential from oil from the leaking tank to spill

into the Tasman Estuary. Eight fire appliances and about 40 firefighters,

with engines from Richmond, Stoke, Wakefield and Nelson battled the blaze.

The fire was under control by 7am this morning, but controlling the fire

was initially dangerous and difficult due to the enclosed nature of the

fire and because of the threat of explosions or flash backs, the chief

fire officer said.

Oil leaking from the fire was also burning, causing running fires towards

drains and buildings, which also made accessing the fire tricky. Firefighters

were only able to reach the fire once they had significantly cooled the

tank, and could remove the hatches off the top of the tank, the chief

fire officer said. "We had to prise the hatches off very slowly,

as we didn't want to get a flash back." "When that happened

(getting the hatches off) we were able to cool it quicker and the fire

went out." The chief fire officer said the oil leaking from the tank

was contained in a holding reservoir at the back of the MDF plant.

There was no threat of oil leaking into the estuary, as the sluice gates

were shut and the level of water in the reservoir was low, the chief fire

officer said.

Workers at the plant were evacuated during the fire, and the factory

was partially running againby nine o'clock this morning, the chief fire

officer said. The cause of the fire was not known this morning. Damage

from the fire was contained to the tank and the area around it. Nelson

Pine Industries managing director was unavailable to comment this morning.

The MDF plant employs 275 people and produces and exports medium density

fibreboard and laminated veneer lumber.

WORKER HOSPITALISED AFTER GAS EXPLOSION AT TUAS COMPANY

A worker suffered serious head injuries when an explosion occurred at

a company producing various natural gases in Tuas. The incident took place

on Wednesday at Linde Gas Singapore Private Limited, and the technician,

a Chinese national in his twenties, was sent to the National University

Hospital where he was warded.

Singapore Civil Defence Force (SCDF) officers received a call around

10.40am about the incident. "I heard a very loud bang. I saw some

smoke and then there was smell of gas. I was not sure if it was poisonous.

I quickly ran back to my factory," said eyewitness. Fortunately,

there was no fire as a result of the explosion caused by two gas cylinders,

each weighing 50 kilogrammes.

When civil defence officers arrived at the scene, they found about 20

other unaffected cylinders in the gas filling room. "What SCDF did

was to make sure that there was no further threat of fire or any explosion

by shutting down the plant first. After that, we moved in into the gas

filling room to remove all the unaffected cylinders," said the Commanding

Officer, Tuas Fire Station. This is the first time an explosion has happened

at Linde Gas, a German company which has been operating out of Singapore

for nearly five years.

Both the company's management and the SCDF are working closely to find

out how the explosion happened. The company deals in speciality gases

for a range of industries, including chemical, medical and electronics

manufacturing. It employs 28 staff, most of them Singaporeans.

View full story here

SOUTH AFRICA'S SASOL INVESTIGATES GAS LEAK,17 HURTSouth

South African synthetic fuels maker Sasol said on Thursday it was investigating

a fire and hyrdofluoric gas leak at its Natref oil refinery near Johannesburg

in which 17 people were injured. The company also said it had appointed

US safety consultancy Du Pont to review procedures and management after

a series of accidents at its plants since last June in which at least

13 people have died. "Sasol remains highly concerned about the trend

in accidents ... every effort is being made to reverse this trend and

is the top priority for the group," a company spokesman said in a

statement.

After the latest accident on Wednesday, Sasol is removing product inventory

from the Natref refinery at Sasolburg, south of Johannesburg, which it

jointly owns with French oil giant Total, it said. This might result in

minor releases of product under controlled conditions but is not a matter

of concern, it said. "It is suspected that a seal on a pump became

defective, leading to the gas leak, which ignited," the company spokesman

said. "Of the 17 employees and contractors taken to a local hospital

... 16 have been discharged, and only one remains in hospital for further

observation and shows no signs of any complications," he added.

In line with normal procedure, South Africa's Labour Department is also

investigating the accident. Refinery production was unaffected because

the plant was undergoing routine maintenance, and a preliminary assessment

showed that the incident did not affect the environment, the company said.

View full story here

DIESEL FUEL SPILLS INTO CLERMONT COUNTY CREEK

Emergency crews in Clermont County and a HazMat team are trying to clean

up an accident that ended with a large diesel fuel spill. Williamsburg

fire officials say a car and a semi carrying a trackhoe collided head-on

on State Route 133 just south of Williamsburg Tuesday night. The semi

ran off the road and into a creek, then started leaking around 100 gallons

of diesel fuel into the water.

The truck's driver appeared to have minor injuries, but the driver of the

car was trapped for almost 45-minutes. Hazmat teams were on the scene late

Tuesday night trying to contain the spill. They were digging a trench to

siphon the fuel out of the creek. Officials from the Environmental Protection

Agency (EPA) and the Ohio Department of Natural Resources (ODNR) are expected

to inspect the crash site Wednesday.

A TRUCK CARRYING 30,000 LITRES OF AVIATION FUEL SPARKED A SPECTACULAR FIRE IN WAIKATO TODAY.

The smouldering truck was a molten mess early this morning, while a massive

plume of smoke floated high in the air above the scene near Ngatea on

the Hauraki Plains.

The blaze started about 3.15am on SH27, and the truck was destroyed.

The driver escaped uninjured. Nine fire trucks from Ngatea, Paeroa, Tahuna,

Auckland and Hamilton raced to the scene. The road was still closed this

morning while more than 30 firefighters cleaned up the mess and took safety

precautions. The road was expectedto reopen by lunchtime.

The Fire Safety Officer said it was decided to let the aviation fuel

burn off rather than risk environmental damage by putting it out. The

fully laden tanker was bound for Taupo Airport, the Fire Safety Officer

said. Investigations into how the fire started were under way, but Hamilton's

deputy chief fire officer said initial indications were that a tyre blow-out

or a malfunction in the wheel assembly caused sparks that ignited a small

amount of the fuel.

The chief fire officer said it was lucky the truck was full with fuel

because an air chamber could have caused a large explosion. He praised

the truck driver for pulling into a lay-by when he realised the danger

unfolding. "There are a large number of trucks on the highways in

the Waikato area that are carrying bulk hazardous substances and fuel,

and the potential for incidents like this are quite high," the chief

fire officer said.

POTENTIAL OF CATASTROPHIC FIRE FROM TERRORIST ATTACK

WORRIES LNG OPPONENTS

The Algerian inferno a year ago undermined industry arguments that the

modern era of LNG transport is inherently safe.

It also became rallying point for groups fighting proposed new LNG terminals

in their towns. Companies are beginning to gear up for LNG imports. As

many as a dozen new terminals are expected over the next decade. To many

energy experts, fear of a devastating LNG fire from an accident or terrorist

attack is the toughest obstacle facing the industry.

A recent government report, the most comprehensive examination of LNG

tanker risks to date, concluded that terrorists have the capability to

tear a huge hole into a tanker. That would unleash a spill and intense

fire that would cause major injuries and burn buildings as far as one-third

of a mile away. People a mile away could suffer second degree burns, the

report said.

LNG imports are widely acknowledged to be crucial in meeting future natural

gas needs. Yet public concern about safety has led more than a half-dozen

communities to reject an LNG import terminal or rally against a proposed

facility. Critics want double-hulled tankers carrying more than 30 million

gallons of LNG barred from traversing waterways in populated areas or

within a mile of homes, schools and office buildings. Industry advocates

say the safety risks are exaggerated, citing a 40-year history of more

than 35,000 shipments of LNG worldwide without a significant release of

the fuel or a fire. They also argue that the Algerian accident, involving

a liquid gas leak and explosion set off by a spark from a boiler, could

not happen at U.S. facilities because of different equipment and design.

The recent federal study by Sandia National Laboratory found potentially

harrowing consequences from spills. The report also said the chance of

an intentional spill could be reduced greatly with "a halo of security"

for arriving tankers. "We can significantly reduce the likelihood

of a terrorist attack occurring with security planning and mitigation,"

says a deputy assistant secretary for fossil fuels at the Energy Department,

which commissioned the Sandia study.

The executive director of the Center for Liquefied Natural Gas, an industry

trade group, does not dispute the Sandia report's assessment of a "worst

case" LNG accident. But, he says, the "remarkable safety record"

and close government scrutiny of LNG shipments make such an accident a

"low probability." The Sandia study, in fact, concludes the

risks of an accidental release of LNG from a tanker are small. But it

is post-Sept. 11 fears about terrorism that bring a new dimension to the

debate over LNG transport. For nearly half a century, the emphasis has

been on preventing human error, not intentional acts.

Since the terrorist attacks, the Coast Guard has imposed tighter security

on LNG tankers. Measures include four days notice of a tanker's arrival,

information on its last ports of call and crew, and special sweeps and

vessel boardings. Rear Adm. the Coast Guard's assistant commandant for

marine safety and security, said the Sandia findings will help "in

further refining our risk reduction efforts." The study's classified

version includes specific attack scenarios and their likely impact.

As a frosty liquid, kept at minus-260 degrees Fahrenheit, LNG cannot

explode or catch fire. Various studies agree that if a tanker is breached

by a bomb or missile, the liquid flowing from its icy storage instantaneously

would become a gas and ignite. The result: an extremely hot fire, as wide

as three football fields. The Sandia study concluded that a terrorist

attack could blast a large enough hole -- and possibly several holes --

that would cause cascading damage. The cold liquid and intense heat of

the fire would weaken adjacent tanks, causing them to fail and adding

to the size of the spill and the blaze atop the water. "The fire

from such a spill would be very large ... perhaps up to a half-mile in

diameter, or larger if more of the containment system failed," says

a professor of chemical engineering at the University of Arkansas. "We

have no experience with fires this large, but we do know they could not

be extinguished. They would have to burn themselves out," says the

professor, who over three decades has studied the likely impact of LNG

fires.

The industry's good safety record has actually made it harder to determine

how much damage a large spill might cause. The only tests have been on

spills of 10,000 gallons of LNG, not the 3 million gallons or more that

scientists believe would be released if a tanker were breached by a bomb

or missile. Computer models about a major LNG vessel spill have produced

widely different results. One study assumed only a 3-foot hole and that

waves would limit the spread of the fire. A second study assumed a breach

of more than 30 feet across, resulting in a rapid spill and much bigger

fire. These models are uncertain because they rely on assumptions "about

which fair-minded analysts may legitimately disagree," the Congressional

Research Service said.

The Sandia study was ordered with the hope of resolving some of that

disagreement. It found "that the worst that can happen or near worst

... is really more than the industry has admitted so far," says a

semi-retired professor at the Massachusetts Institute of Technology. Since

1970, the professor has argued the government and industry were understating

the potential dangers of a major fire.. In an interview, he said the Sandia

study documented "that the worst that can happen is very bad."

He scoffed at the suggestion that the impact of an LNG spill and fire

could be mitigated. "The fire is over in five minutes," he said.

"You can't sound fire alarms and tell people to shuttle away from

the harmful effects."

A Repuplician Politician, who has pressed the Bush administraion for

tighter restrictions on siting LNG terminals, said the Sandia report has

"destroyed any argument that LNG facilities should be based in urban

areas." A 1979 law says LNG regulators should "encourage"

remote siting of import terminals. The politician however, says regulators

have ignored Congress' intent and continued to consider sites in densely

populated areas, especially in the Northeast where LNG facilities are

being proposed in Providence, R.I., and in Fall River, Mass., and where

tankers would travel through the heart of the community.

A senior official at the Federal Energy Regulatory Commission who is

involved in LNG terminal siting, says he has no illusion about the prospects

of an LNG-fed inferno spreading over water. "It's a fire that can't

happen," he said from his office near the Capitol. He meant that

it cannot be allowed to happen. But he also insists that federal security

requirements are sufficient to prevent terrorists from causing a spill.

"If I had to worry about my safety, or my family's safety, I'm a

lot more worried working this close to the Capitol building than I would

be living close to an LNG facility," he says.

Energy regulators have a dozen LNG terminal site proposals under consideration.

They have approved expanding the four existing terminals and have given

a green light to three new ones on the Gulf Coast. Regulators must ensure

the risk "is as close to zero as possible" while recognizing

the need for reliable and affordable supplies of LNG, said the commission's

chairman in an interview. But he added that he and fellow commissioners

"also recognize there is an economic need here if you want to have

reliable and affordable supplies" of natural gas. A native of Port

Arthur, Texas, the commission's chairman says three LNG import sites "are

going in my hometown potentially" and that has given him a strong

incentive to make sure the public is not in danger. But in Fall River,

Mass., the Mayor is not convinced that the government is committed to

protecting the 5,000 people who live or work within a mile of a proposed

LNG terminal in his town.

FERC officials acknowledged in a report that a tanker would have to maneuver

up the Taunton River, which cuts through the heart of Fall River, and

under four bridges, including one carrying an interstate highway. But

the report also said risks from a possible terrorist attack on a tanker

"can be managed." The commission has yet to rule on the project.

"It's downright foolish," the Major said in a telephone interview.

They want the town to bear "a risk no American citizen should be

asked to bear when there are alternatives."

On the Net:

Federal Energy Regulatory Commission:

Center for LNG

Energy Department

CHEMICAL SPILL SICKENS DOZENS AT JACKSON COUNTY PLANT

Hazmat crews spent hours at an auto parts plant in Crothersville Friday,

trying to determine what caused a chemical spill there. It happened around

7:30 Friday morning at Aisin Drivetrain, Inc. WAVE 3's Frances Kuo reports.

Fire officials are still trying to determine a cause, but they believe

hydrochloric acid got into a mixture that an employee was working with.

"Our environmental technician was conducting a normal daily activity

where he was cleaning out the system, and during that cleaning process,

he noted the chemical reaction," said Vice President of Operations

at Aisin.

Crews from the Crothersville Fire Department, Jackson County EMS and

hazmat teams didn't get the call until an hour-and-a-half later, when

people started showing symptoms. "The physical reaction to this is

kind of a delayed type of thing, so it was more or less around 9 o'clock

when people started getting sick," said Asst. Chief of the Crothersville

Fire Department. "A lot of people were vomiting and having a lot

of problems with nausea." More than 100 people were evacuated from

that part of the building, and 28 were taken to area hospitals and decontaminated.

Authorities say they acted quickly as soon as they arrived at the scene,

which prevented the situation from becoming worse. "Not knowing for

sure what type of chemical it was, obviously you're better safe than sorry,

you get everybody out," the Asst. Chief Fire Dept said. He also said

overhead doors in the affected area helped clear some of the vapor. As

of Friday evening, two workers are still at Seymour Hospital for observation.

The factory was fully operational Friday afternoon.

View full story here

A MAN LOOKS AT DEAD CATTLE IN A RIVER AFTER OIL SPILL IN VERACRUZ

A man, his face covered against the fumes, looks at dead cattle in and around a river in Aguadulce, Veracruz, after a Pemex pipeline ruptured and semi-refined gasoline, known as naphtha, spilled into a local river January 27, 2005. The director of state oil monopoly blamed the spills on years of lack of investment in maintenance of ducts and pipelines.

View full story here

MAN REMAINS IN CRITICAL CONDITION AFTER REFINERY CHEMICAL SPILL

A man injured at the Alcan Gove refinery at Nhulunbuy in the Northern

Territory remains in a critical condition a week after a spill left chemical

burns on most of his body. The victim was flown to Royal Adelaide Hospital

in South Australia for treatment to burns sustained when the sodium hydroxide

leaked from a container he was depressurising.

The Alcan Gove bauxite mine and alumina refinery is located at Nhulunbuy

on the Gove Peninsula in the east Arnhem Land region of Australia's Northern

Territory. The Northern Territory Department of Industry isexpecting the

report from an investigation into the incident later today.

View full story here

GAS STATION FIRE

Fire crews say it took nearly half an hour to get the blaze under control.

Jacksonville fire investigators are looking into what started a fire

at a local gas station Monday. It happened at the Citgo station at 3260

Beach Blvd. That gas staion is now closed. Fire crews say it took nearly

half an hour to get the blaze under control. There were no injuries, but

the convenience store at the gas station had a lot of damage. Workers

at the station say they were having electrical problems yesterday, but

that has not yet been ruled the official cause of the fire.

View full story here

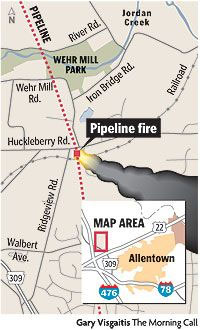

EXPLOSION FORCES EVACUATIONS IN S.WHITEHALL

An underground gasoline pipeline ruptured and exploded Tuesday morning

in South Whitehall Township and forced the evacuation of homes and businesses

in the area, officials said.

There were no immediate reports of injuries or property damage in the

explosion, which happened around 6:30 a.m. on Huckleberry Road near Wehr

Mill Road in South Whitehall Township, a supervisor for the Lehigh County

Emergency Management Agency said.

Emergency workers shut off a valve leading to the pipeline, and firefighters

are waiting for the fire to burn itself out. The FBI and the federal Bureau

of Alcohol, Tobacco and Firearms have responded to the explosion. Utilities

in the surrounding area were shut off as a precaution, according to police

scanner reports. South Whitehall police said the fire is stemming from

an 8 inch Exxon/Mobil gasoline pipeline.

Police responded to reports of an explosion shortly after 6:30 a.m.,

said the Police Sgt. Police evacuated nearby residents from Walbert Ave.

to the Turnpike and Old Century Road to Bradford Drive. A statement from

Mobile Pipe Line Co. said the company experienced a leak of petroleum

products on its pipeline system in the area which apparently ignited and

caused the fire.

People were first evacuated to the South Whitehall Township municipal

building, but smoke forced them to the Parkland Area School District administration

buildings. The Township Manager said the EPA and DEP were both on the

scene and they don't believe there's an airborne hazard from the large

plume of smoke that resulted from the fire.

The Federal Aviation Administration has restricted flights in the area

from entering airspace within a mile of the explosion. State officials

say people with respiratory ailments living in the area should stay inside.

Traffic in the area had been snarled, but Parkland Area School District

officials said it did not affect students significantly in terms of getting

to the high school in the morning commute. All utilities are operational

at the high school, which is about a mile away from the explosion site.

A resident who lives on Lapp Road in the township, less than a mile to

the south of the explosion site. She said she was up around 6:30 a.m.

getting her sons ready for school but didn't hear any explosion. "First

I noticed is going outside and seeing the black cloud, it's been there

all morning," she said. "But there's no odor that we noticed,

the wind is going in the other direction." The resident said utilities

at her home had not been affected.

According to its Web site, ExxonMobil Pipeline Co. and its affiliates

are engaged in transporting approximately 3.5 million barrels per day

of crude oil, refined petroleum products, liquefied petroleum gases, natural

gas liquids, and chemical feedstocks through 11,000 miles of pipeline

in 21 states, the Gulf of Mexico, and Canada.

USA, WASHINGTON, FEBRUARY 1 2005. INPUT REQUESTED ON INTERMODAL TRANSPORT

TANK REQUIREMENTS

DOT, RSPA, Office of Hazardous Materials Technology, and the American

Society of Mechanical Engineers, International (ASME) have established

a committee to consider technical requirements for transport tanks used

to carry hazardous materials.

The committee of government and industry stakeholders is developing a

new section of the ASME Code, which will include requirements for the

construction and continued service of transport tanks used for the carriage

of dangerous goods, as well as criteria for accreditation of manufacturers

of these tanks. The initial phase of this effort focuses on requirements

for portable tanks and ton tanks.

Currently the Hazardous Materials Regulations (HMR) adopt certain provisions

of various codes and standards, such as the ASME Boiler and Pressure Vessel

Code, for the design of pressure vessels, and add pertinent specific modal

requirements that apply to transport tanks. The proposed section of the

ASME Code is intended to make the technical requirements for many transport

tanks under DOT jurisdiction more consistent. It is anticipated that the

documentation developed through this effort will be suitable for incorporation

by reference within the HMR after public comment is received through the

normal regulatory process.

MEXICO, MEXICO CITY, FEBRUARY 1 2005. PEMEX WANTS $9 BILLION TO FIX PIPES,

OIL SPILLS CONTINUE

Mexican state oil monopoly Pemex Monday confirmed an oil spill in Veracruz

state. It's fifth spill of oil or fuel in four months as energy authorities

said $9 billion was needed to fix the country's old and rusting pipeline

network.

Pemex said the Jan 26. crude oil spill occurred near the town of Hueyapan

de Ocampo, Veracruz. A Pemex spokeswoman in the nearby Gulf of Mexico

port of Coatzacoalcos told Reuters around 45,000 liters (283 barrels)

of oil had seeped into the subsoil from a faulty pipeline. She said the

leak was caused by corrosion.

Local media have quoted Veracruz Governor as saying the spill could pollute

underground water sources. A joint statement by Pemex, Mexico's energy

and environment ministries, and environmental watchdog Profepa said Pemex

needed to invest 100 billion pesos ($9 billion) over the 2006-2008 period

for a huge backlog in repairs to 36,738 kilometers (22,961 mile) of aging

pipeline.

The recent spate of spills has thrust attention onto the state of pipes

pumping oil, gasoline, natural gas and chemicals around the Gulf of Mexico

states of Veracruz, Tabasco and Campeche, where the oil industry is centered.

Pemex chief is due to appear before Congress later Monday to discuss the

situation.

Mexico's IMP oil research institute estimates that half of Mexico's pipelines

are more than 30 years old and corroded. While Pemex has cleaned up the

worst of the spills and trucked bottled water into contaminated areas,

residents and fishermen were still suffering the aftermath, illustrated

by photos in the local media of dead fish and oil-stained earth. Pemex,

which pays taxes worth 61 percent of its revenue, has complained for years

that it cannot operate properly with the budget Congress gives it. Last

week Pemex said pipeline repairs would cost $3 billion over six years.

Mexico is the world's No. 9 oil exporter, selling much of its 1.95 million

barrels per day to the United States.

A reform to ease Pemex's tax burden by trimming royalties on oil produced

from new oilfields has been held up in Congress by opposition Senators

wary of any changes to Pemex's statute. The company is spending the bulk

of its $11 billion investment budget this year on exploration and production,

its main focus based on concerns that output from its largest oilfield

will start declining from 2006. Pemex officials at a spill of toxic naphtha

fuel a week ago near the town of Agua Dulce, Veracruz, told Reuters over

the past weekend that the company needs to extend a computerized leak

alert system to its entire pipeline network.

View full story here

RIVER DILUTES DANGER OF SPILL

It will be at least Wednesday before about 200 East Deer residents evacuated

because of a train derailment and chemical spill are allowed to return

home. Monday morning's derailment left a tanker carrying anhydrous hydrogen

fluoride upside down in the Allegheny River near the New Kensington bridge.

The gaseous chemical, when mixed with water, turns into a corrosive acid

called hydrofluoric acid, said an emergency response coordinator with

the state Department of Environmental Protection.

Although the emergency response coordinator described hydrofluoric acid

as "one of the nastiest acids around," he said there wasn't

a significant effect on the river water. "It appears to be a slow

enough leak, and there are billions of gallons of water to dilute it,"

the co-ordinator said. "So far, there's not a problem for drinking

water. They're monitoring it." Thirteen cars of an 84-car Norfolk

Southern train derailed about 5:30 a.m. on tracks between Freeport Road

and the Allegheny River in East Deer. No injuries were reported. Another

tanker is also in the water but it is not leaking. Officials did not say

what it is carrying.

Chief Allegheny County Emergency Management coordinator, said it could

be at least Wednesday before crews can empty the leaking tanker and remove

it from the water. Two other derailed cars also contained anhydrous hydrogen

fluoride, but neither was leaking, officials said. The chief Allegheny

County Emergency Management coordinator said workers will begin emptying

those cars today, which could take about 12 hours per car. The evacuation

order affected about 200 residents within a half-mile of the crash site

on the East Deer side of the river. The New Kensington bridge was shut

all day, and all boats were barred from the river between the Tarentum

and New Kensington bridges.

East Deer commissioners Chairman said Oakmont Water Authority stopped

taking water from the river from about 6 to 8 p.m. because of increased

fluoride levels, but service was unaffected. The tanker cars hold 15,000

to 20,000 gallons, but officials could not say how much of the chemical

was being transported. The commissioner said a "good bit" of

the chemical appeared to be leaking into the river, because the tanker

was getting lighter. "The car being in the water is actually working

to our advantage," the commissioner said. "A scrubbing effect

is occurring under the water." The emergency response coordinator

said anhydrous hydrogen fluoride reacts with water, making it too dangerous

for divers to get close enough to pinpoint the leak. Crews determined

the leak is near a dome on top of the tanker, which is underwater. The

water is rippling and bubbling near that spot, and a small white vapor

cloud is above it, the emergency response coordinator said.

One concern is keeping the gas from leaking into the air once the tanker

is lifted out of the water. Inhaling the gas would cause instantaneous

burning of the eyes and lungs, the emergency response coordinator said.

He said hydrofluoric acid is so corrosive, "it will eat through glass."

When it's transported in its acidic form, containers must be lined in

wax, the emergency response coordinator said.

Officials are still investigating what caused the wreck Chief Allegheny

County Emergency Management coordinator said that while no cause has been

ruled out, sabotage seemed unlikely. Determining the cause could take

weeks, said Norfolk Southern spokesman . He said interviews with conductors

ruled out operator error, and the three members of the train crew were

given a routine drug and alcohol test. "It's really a processof elimination,"

the spokesperson said. "We need to look at the equipment and track

and start ruling things out," He said the first priority is safety

and getting the tracks back together. The train was traveling from Conway

to Allentown, where the cars were to be put on other trains for delivery,

the spokesperson said. It carried products including lumber, flour, plastic

pelletsand corn syrup.

View full story here

USA, COLO, FEBRUARY 2 2005. GAS PUMP EXPLOSION COSTS COLORADO C-STORE

The owners of a Frisco convenience store where a gas pump exploded last

year must pay nearly $100,000 dollars for serious and willful violations

of the Occupational Safety and Health Act, according to the Associated

Press.

A maintenance clerk at the Loaf N' Jug was trying to fix a slow gas pump

when a fuel leak occurred. The gas ignited and the pump exploded, injuring

seven people.

The OSHA violations were for improper training and a lack of safety equipment,

including the metal hammer used to break the glass that covered an emergency

shut-off switch and protective equipment for workers' eyes, face and hands.

The company has 15 working days to fix the problems and pay $92,500 in

fines, or contest the findings.

LEAK SUSPECTED IN FIERY PIPELINE BLAST - GASOLINE EXPLOSION

SPURS EVACUATION OF DOZENS; PASSING CAR MIGHT HAVE SET IT OFF

The gasoline explosion and fire at a pipeline in South Whitehall Township

at dawn Tuesday chased dozens of residents from their homes, some in little

more than their nightclothes, and sent a towering pall of sun-dimming

smoke drifting over the Lehigh Valley.

Gasoline from the pipeline at Huckleberry and Wehr Mill roads continued

burning early today, and the evacuated residents were offered overnight

shelter at two hotels. Authorities said they would have to wait for the

fire to burn out before conducting a full investigation, but speculated

that a leak in the pipeline might have been ignited by a passing car.

Similar events along the nation's massive pipeline network in recent

years, some of them deadly, have been blamed on equipment failures, corrosion

and related causes. No one was injured in the 6:30 blast, not even two

motorists whose vehicles were engulfed by flames as they drove past. Heat

from the fire melted the siding on the nearest home.

The FBI and the Bureau of Alcohol, Tobacco, Firearms and Explosives were

at the scene, but authorities downplayed the possibility of terrorism.

''There's no reason to think it's anything other than an accident,'' said

operations manager for Mobil Pipe Line Co., the line owner. The company

is a subsidiary of petroleum giant ExxonMobil. The line is one of three

major pipelines that cross the Lehigh Valley.

The explosion happened at an above-ground junction station where gasoline

is diverted from the 8-inch main pipeline into a 6-inch spur line that

leads to Allentown. The operations manager said it is possible one of

the cars passing the fenced station at the time of the explosion somehow

ignited leaking gasoline. That theory was bolstered by the account of

a local resident schoolteacher, who lives in the 4000 block of Old Sentry

Road in South Whitehall. She said she saw liquid shooting out of the junction

as she drove by at 6:25 a.m., minutes before the explosion, and didn't

have a chance to call the emergency number posted at the site.

The fire raged as officials allowed gasoline remaining in the line to

burn off. Officials said the closest shutoff valves on the north-south

line were 10 miles away in each direction, accounting for the long burn-off

period. Firefighters built a sand dam to contain whatever gasoline hadn't

burned, and vacuum trucks were brought in to suck up the liquid. ''There

has been some fuel spilled on the ground but no one seems to know what

quantity,'' said Township Manager worrying about possible tainting of

the area's residential and municipal wells. The state Department of EnvironmentalProtection

tested the air and water in the area and discerned no immediate health

threats. An emergency response manager with the agency, said the groundwater

would have to be monitored for some time to make sure wells are not tainted.

''The long-term impact is a concern,'' he said. Authorities evacuated

43 homes and advised people across a larger area to stay indoors if they

are prone to breathing problems.

The residents were to be kept out of their homes overnight, though they

were allowed back briefly to gather belongings. They were escorted by

firefighters who brought instruments to test for volatile vapors. Airspace

over the scene was restricted for a while, but that did not affect operations

at Lehigh Valley International Airport, said LVIA's top official.

A shelter was established at Parkland School District's Troxell Administration

Building. ''I didn't even get my coat,'' said another resident, recounting

how she and her husband, fled in their car on Huckleberry Road as gasoline

burned in the gutters on either side of the street. Yet another resident,

a diabetic, left the house in a T-shirt and slippers and forgot his insulin.

''For a few minutes, it looked like we were in big trouble,'' said another

resident, whose Brickyard Road home sits just yards from the station and

was closest to the explosion. Firefighters doused the house to stop the

siding from melting. ''It looked like the whole neighborhood could have

been gone,'' he said. The wife of the resident who lives closest to the

explosion said she heard three loud booms around 10 seconds apart.

The 480-mile pipeline carries gasoline, diesel fuel and heating oil from

Paulsboro, N.J., near Camden, to Buffalo, N.Y., said Mobil Pipe Line spokesman.

The spur to Allentown is 7 miles long. Officials said the portion of the

pipeline in South Whitehall was last inspected in November by the Office

of Pipeline Safety, a division of the U.S. Department of Transportation.

The pipeline spokesman said the inspection revealed no ''findings,'' or

major problems.

An ExxonMobil spokeswoman said the pipeline dates to 1950. It courses

through the Lehigh Valley, roughly paralleling the Turnpike. At the time

of the blast, the line was carrying gasoline under pressure of 1,400 pounds

per square inch. ''The flames were at least 75 feet in the air,'' said

a resident who lives on Loring Drive off Huckleberry Road. ''The smoke

… it was a like a big mushroom cloud.'' South Whitehall Commissioner,

who lives on Brickyard Road, estimated the height of the explosion at

175 feet, based on scorch marks in the trees.

Several other residents who live close to the site didn't hear the explosion.

A local couple, who live in the 3700 block of Huckleberry, didn't know

anything was amiss until their son called to ask if they needed a place

to stay. Another residetn who lives in the 3800 block of Huckleberry,

said he heard a muffled thud. ''You kind of knew it was an explosion,''

he said. Another resident of Brickyard Road was walking a dog he calls

''The Schnutz'' when he saw the explosion and watched flames race along

the ground. A resident who has lived at Huckleberry and Brickyard roads

for 56 years, said the blast shook her out of a sound sleep. ''It sounded

like Trojan going up again,'' she said, referring to a gunpowder plant

that operated in the area until the 1970s and was the scene of several

major explosions. Another Huckleberry Road resident said he heard a small

explosion followed by a larger one. ''I looked out my picture window and

there was a ball of fire,'' he said. The flames ''were as high as the

tops of the trees.… I thought initially it was an oil truck or gasoline

truck exploding.'' Another resident a self employed physical therapist,

was overlooked in the evacuation. Noticing how quiet the neighborhood

had grown in the hours after the explosion, she went for a walk and encountered

a surprised firefighter who said, ''Where have you been? We thought we

got everybody out!''

The Pennsylvania Emergency Management dispatched two people from its

eastern regional office in Hamburg, the PEMA Director said Although PEMA

is technically the lead state agency in any disaster, the Director said

county officials had the situation Tuesday well in hand and that PEMA

was primarily offering counsel and technical support.

The explosion played havoc with the morning rush hour. Parkland Superintendent

said homeroom period at Parkland High School was extended to allow for

late-arriving students. ''Traffic was a little crazy,'' she said. ''Everyone

was tied up this morning.'' At a 6 p.m. news conference at the South Whitehall

Municipal Building, officials could not yet estimate the amount of gasoline

lost in the incident. The Parkland Superintendent said a fairly accurate

tally eventually will be made.

The DEP spokesman said that while no immediate groundwater contamination

is known, bottled water will be provided ''as a precaution'' for residents

of evacuated homes served by private wells. The public water supply is

safe, he said.

Officials had yet to determine what ignited the gasoline. The operations

manager for Mobil Pipe Line Co declined to speculate about what other

causes might be possible, other than one of the passing cars. ExxonMobil

is paying the hotel and food bills and related expenses for the evacuees,

and the Red Crossprovided meals and drinks.

NO SERIOUS INJURIES IN FORKLIFT TANK BLAST

A forklift leaking propane exploded early Tuesday at a freight warehouse,

injuring an employee and causing firefighters to duck for cover as fragments

of burning metal flew past them. The explosion and fire was reported about

1:15 a.m. at Velocity Express, 1217 Minters Chapel Road. An employee,

who fire officials did not identify, suffered burns as he attempted to

stop the leaking propane, a fire official said. The employee was taken

to Baylor Regional Medical Center at Grapevine, but his condition was

unavailable. His injuries were not believed to be life-threatening, fire

officials said.

Employees told firefighters that they were attempting to replace a propane

tank on the forklift when it began to leak. About five employees were

in the area, according to fire reports. "The liquid propane vapors

became too much for the employees, so they ran out of the area,"

said Grapevine Fire Marshal. "Within 30 seconds after they left,

the forklift exploded. The vapors probably contacted the heat of the forklift

and that caused the explosion." The explosion ignited a fire on the

forklift and a nearby trailer loaded with office supplies, causing about

$15,000 damage, the Fire Marshal said. The warehouse was not damaged,

he said. The Fire Marshal said firefighters were lucky they were not injured

by the fragments. "The employees got out just in time, and if firefighters

had gotten there a few seconds earlier, they would have been hit."

AIRPORTS COMMISSION AND FUEL COMPANIES FINED FOR EXTENSIVE FUEL LEAKS

AT AIRPORT

The Metropolitan Airports Commission and two fuel companies at Minneapolis-St.

Paul International Airport have been fined $125,000 and must spend more

than $3 million on various airport improvements for a series of fuel leaks

that occurred at the airport two years ago.

The penalties are contained in an agreement reached between lawyers at

the Minnesota Pollution Control Agency, the Metropolitan Airports Commission,

Aircraft Services International and the Minneapolis Fuel Committee.

The agreement, which will be considered by a MAC committee next week,

is the product of a two-year investigation into why thousands of gallons

of jet fuel leaked at the airport. The leaks, which were discovered in

February 2003, contaminated soil beneath the airport and allegedly drained

through storm sewers into the Minnesota River.

GAS PUMP EXPLOSION COSTS COLORADO C-STORE

The owners of a Frisco convenience store where a gas pump exploded last

year must pay nearly $100,000 dollars for serious and willful violations

of the Occupational Safety and Health Act, according to the Associated

Press. A maintenance clerk at the Loaf N' Jug was trying to fix a slow

gas pump when a fuel leak occurred. The gas ignited and the pump exploded,

injuring seven people.

The OSHA violations were for improper training and a lack of safety equipment,

including the metal hammer used to break the glass that covered an emergency

shut-off switch and protective equipment for workers' eyes, face and hands.

The company has 15 working days to fix the problems and pay $92,500 in

fines, or contest the findings.

OSHA LEVIES FINE IN GAS STATION EXPLOSION

Seven people were injured on Aug. 4 in Frisco when an explosion and fire

at a gas station pump destroyed an RV.

The owners of the Frisco store where a gas pump explosion injured seven

people last year have been fined more than $92,000 by federal workplace

safety officials. The company was cited last week and has15 days to fix

the problems and pay $92,500 or contest the findings, said Denver area

director of the Occupational Safety and Health Administration.

A maintenance clerk at the Loaf N' Jug was trying to fix a gas pump

Aug. 4 when leaking fuel caught fire and the pump exploded. The agency

accused the owners of improper training and a lack of safety equipment,

including the hammer used to break the glass covering an emergency shut-off

switch for the pump. It also said employees had no way of verifying the

pumps were off.

CYANIDE SPILL AT OLD MINE

Cyanide has erupted from a storage tank at an abandoned Northern Territory

mine while contractors hired by the NT Government were trying to neutralise

the chemicals. More than 500 litres of cyanide escaped from a storage

tank at the Mount Todd gold mine near Katherine on the Edith River, southeast

of Darwin, on Tuesday.

Mintech Chemical Industries was hired by the Government at a cost of

$25,528 to remove 700,000 litres of cyanide solution from storage tanks

at the mine after on-site salvagers Aussiequip refused to take responsibility

for it. Territory Mines Department chief executive said that during the

initial neutralisation process in which hydrogen peroxide was introduced

into the cyanide, a vigorous chemical reaction occurred. "The reaction

was due to gases being contained by crusted iron compounds within the

tank as it had been sitting for many years," the chief executive

said. "A quantity of liquid blew out through the vents on the top

of the storage tank. "The reaction caused a rupture between the side

and the roof of the storage tank allowing around 500 litres of liquid

to release."

The chief executive said no one was injured during the eruption. He said

there was also no damage to the surrounding ground or nearby river because

the chemicals were contained by a concrete bund around the site. The chief

executive said the cyanide solution was the last thing left that could

be dangerous on the mine site. "There is a lot of acid rock there

which is something we have to manage as when the water gets into it a

lot of nasties can leach out," he said. "But in terms of dangerous

items this (the cyanide) is the last thing we had to deal with. "But

the longer-term major problems which are the longer-term threats to the

environment are ones that still have to be dealt with."

FINGERPRINT CHECKS NOW REQUIRED OF MANY TRUCKERS - HAZARDOUS-WASTE DRIVERS

AFFECTED BY ANTI-TERRORISM LAW

Every truck driver who wants to haul hazardous materials must be fingerprinted

and undergo thorough background checks under a new federal anti-terrorism

law that started this week. Proponents of the new regulations say they

may help stop criminals or terrorists from getting behind the wheel with

cargo that could be used to explode buildings or unleash biological or

chemical threats.

The problem is some local truckers think it's a waste of time. The new,

tougher restrictions went into effect Monday. They call for the FBI to

use the fingerprints to check each driver's criminal background and immigration

status.

A truck driver who has been hauling big rigs for 26 years, questions

whether the new federal law is foolproof. He transports 8,500 gallons

of gasoline at a time in a big silver tank for Usher Transport Inc. to

places such as Sam's Wholesale Clubs. ''What is fingerprinting going to

do?'' asked the truck driver, as he connected the hose from his rig to

an underground storage tank at the Sam's Club on Harding Place. ''Fingerprinting

won't do nothing. It won't protect this country.'' The check will search

for any violent crimes or terrorist ties, as well as any past mental problems.

Additional rules will take effect May 31, requiring the same fingerprint-based

checks for veteran drivers who are either renewing or transferring the

hazardous materials endorsements on their state-issued commercial driver's

licenses. That affects the 107,047 commercial driver's license holders

with ''hazmat'' endorsements in Tennessee, according to a spokeswoman

for the Tennessee Department of Safety. There are 2.7 million hazmat drivers

nationwide. They drive substances that are flammable, corrosive, poisonous

or that otherwise pose a danger to the public if they're mishandled, including

petroleum products, acids used in industry, explosives, bug- and weed-killing

chemicals used on farms, and solvents.

''We feel that this is an important measure to put in place to ensure

that we were able to create safeguards for transportation of dangerous

commercial products,'' according to a spokeswoman for the Transportation

Security Administration. The head of the Tennessee Trucking Association,

which represents more than 500 trucking companies and industry vendors,

called for support for the new requirements. ''We think it's certainly

a worthwhile effort,'' said the association president. ''It's an extra

layer of security for the transportation of hazardous materials, and we

are doing our part.'' The process will takeabout two weeks to complete,

the TSA estimates. In the past, a private company conducted the background

checks. Now, those reviews will be conducted by the TSA with the FBI's

help. If there are any red flags, the truckers won't get their hazardous

materials endorsement licenses. The law allows them to appeal. Drivers

who have their licenses must renew at least every five years. Some trucking

organizations are opposed to the new rule, calling the new process unnecessary

and ineffective. They also cited ''unfair costs'' to drivers. ''We support

the program, but we believe it was implemented too prematurely,'' president

of the National Tank Truck Carriers Association, based in Alexandria,

Va. ''Within the various states, we just do not believe that there are

enough facilities that have been established to accomplish the fingerprinting.''

President of the National Tank Truck Carriers Association argued that

the new initiative is not ''user-friendly to drivers.'' ''These drivers

will have to travel some extensive distances at least twice: Once to get

fingerprinted and once — presuming they passed the test —

to go back and get their licenses,'' said president of the National Tank

Truck Carriers Association, whose members of the association employ about

55,000 drivers. ''For truck drivers who are constantly on the road, this

means they are going to have to do it either on their private time or

take time off and lose pay.'' The fees vary from state to state and range

from $25 to $99 per driver, trucking companies said.

There are some concerns among drivers whether the fee should be paid

either by them or by the company for which they haul. Some say any initial

hardships — either financial or timewise — for the trucker

is worth it for the country's safety. ''It's not a matter for discussion,''

said terminal manager of Highway Transport Inc. in Nashville that hauls

gas. ''We just roll with it. Most people have the attitude that the reason

behind the program is good enough for why it has to be done. With the

type of hazardous materials we handle, we wouldn't want it to fall into

the wrong hands.''

The new federal requirements were supposed to take effect in 2003, but

they were delayed a few times after states complained about the deadline

for setting up the fingerprinting system, said president of the National

Tank Truck Carriers Association said. ''Our stakeholders indicated they

were going to have trouble meeting that deadline, so we worked with them

to establish an appropriate timeline, and that deadline was'' Monday,

she said.

Nashville-based Integrated Biometrics Technology landed a contract with

the TSA to implement and operate the fingerprinting system. The system

will get rid of the old ink prints that would take weeks for the FBI to

process. It will electronically scan the driver's prints, forward them

to the FBI's fingerprint-processing center and provide results to the

TSA in about a day. Thirty-four states have signed up to use IBT. However,

Tennessee is among the states that will take care of the fingerprinting

on its own.

View full story here

OIL SPILL CLEAN-UP REACHES LOUISVILLE

The effort to clean up the big oil spill from the Kentucky River has

reached Louisville. Clean up crews hired by the oil pipeline company are

now here. Louisville's 4th Street Wharf is about 55 miles away from the

site of the oil spill, but Friday, an oil absorbent boom is now in the

Ohio River near The Belle of Louisville.

A steady flow of oil has been seen in the Louisville area for the past

few days as it started seeping out of the Kentucky River and into the

Ohio. National Recovery Corporation has set up field crews to collect

the oil at Cox Park and other areas.

|