Process Safety Beacon: Communication is the key to safer operations

An incident occurred on a 70-foot (21m) tall equipment platform when a contractor pipefitter applied excess torque to tighten flange bolts on a heat exchanger outlet pipe containing gaseous hydrogen chloride (HCl), causing the pipe to crack and release toxic HCl.

Seven workers from two contract firms were present on the platform. To escape from the HCl release, three insulators climbed down piping on the side of the structure; all three fell to the ground. One worker was fatally injured, and the other two sustained serious injuries.

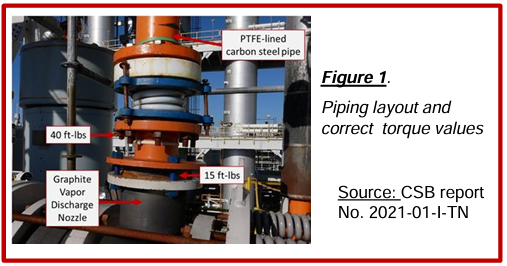

The company described the task to the pipefitting foreman. They provided the manufacturer’s equipment manual containing the torque specification of 40 ft-lbs. for the bolts on the PTFE-lined piping. (Figure 1.) The manual did not include the lower torque requirements for the bolts connecting the PTFE-piping to the graphite nozzle on the exchanger. The company had provided the piping contractor with a heat exchanger drawing, that showed the 15 ft-lb. torque requirement. The pipefitters did not have the design drawing with them when they performed the work.

The foreman led the pipe fitters to the heat exchanger to verbally review the tasks and indicate the specific piping connections they were to tighten. The workers returned to ground level to prepare for the work, and the foreman left the area.

The different torque requirements were not clearly explained and led to the inadvertent over-torquing of the flange bolts on live operating equipment, the equipment fracture, and the release of HCl.

Did you know?

- Reducing mistakes involves good procedures, training, and when needed visiting the area to confirm the details before starting a task.

- Showing some one a situation allows them to see the task, ask questions and get answers before beginning a task.

- Written instructions provide a document that can be taken to where the activity will be done.

- Verbal communications are quickest and easiest butare prone to misunderstanding.

- Unique words used by a particular group are called jargon. They may have a different meaning to those outside the workgroup like contractors.

What can you do?

- Write clear entries in the logbook, round sheets or other notes. Use equipment descriptions or numbers and avoid abbreviations and jargon.

- Point out critical issues and tasks, such as line break locations or hose connections, in the field with those who will perform the work.

- Issue permits to contract workers where the work will be performed. The extra time taken to review the job together may save time and avoid an incident.

- Repeat radio communications back to the sender to confirm you understand the message.

- Ask someone if you are unsure how to proceed. It is better to cause a slight delay than a serious incident.

Important information & instructions should be written.

Critical issues should be shown.

Download the latest Process Safety Beacon

Source: CCPS.