Process Safety Beacon: Inherently Safer Principles

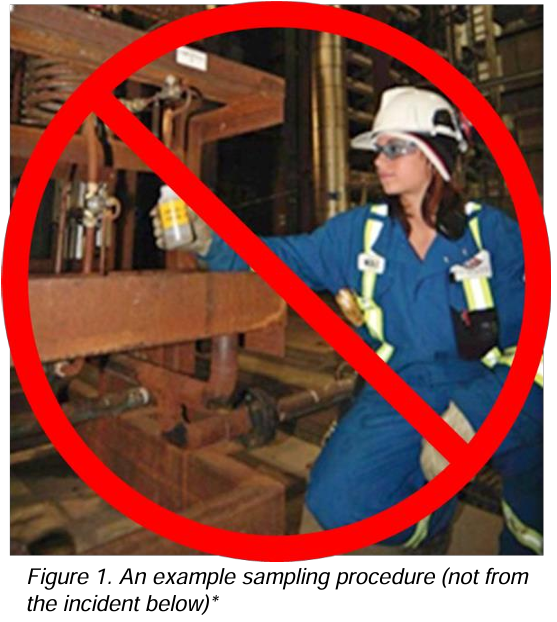

Alkylation is a chemical reaction where an alkyl group is transferred to a molecule. A plant catalytic alkylation reactor produced a mixture of three compounds (ortho, meta, and para isomers). The product composition is a critical specification that needs to be monitored. Sampling was done twice a day (once per shift) at the reactor outlet. The sample was hot and contained hazardous materials. The sampling process had resulted in first aid incidents.

Engineers looked at the statistical quality control data for that sample. The results were consistent. They did not vary much if the raw material quality and reactor temperature and pressure were maintained. The plant applied inherently safer design (ISD) to that operation. Reactor sampling was reduced from twice a day to once a week (ISD – Minimize). They also instituted a practice to take additional samples when there were process upsets, changes in raw material quality, or when there was a replacement of the catalyst. This resulted in waste reduction, cost reduction, and minimized the exposure to hazardous materials for personnel who took the samples and analyzed them. At the same time, they did not compromise the product quality.

Did you know?

ISD strategies include:

- Minimize/Eliminate—Eliminate hazardous material or activity. Reduce inventory of hazardous materials or energy.

- Substitute—Replace a hazardous material or process with an alternative that reduces or eliminates the hazard

- Moderate—Use dangerous materials in a less dangerous form or under less severe conditions.

- Simplify—Designing processes, equipment, and procedures to eliminate unnecessary complexity.

- ISD is not just for design. ISD principles are applicable across the life cycle of a chemical process. A process or a procedure can be simplified, a hazardous material may be eliminated or replaced with safer material anytime from pilot plant to production.

What can you do?

- When you participate in an activity that results in the identification of hazards and safeguards – a Process Hazard Analysis (PHA), incident investigation, pre-startup safety review, job safety analysis (JSA), a plant safety review, look for opportunities to apply ISD principles to eliminate or reduce hazards rather than immediately looking for safeguards.

- Ensure that any ISD options identified are reviewed using your plant Management of Change (MOC) procedures before implementing them. Any change, even one which is intended to eliminate or reduce hazards, has the potential to introduce new hazards or increase the magnitude of other existing hazards.

- Reference: Ganeshmani N. Inherently safer design: Success stories. Process Saf Prog. 2025; 1-7. doi:10.1002/prs.70007

Inherently safer – eliminating hazards rather than managing them!