Process Safety Beacon: Thermal Expansion runs hot and cold!

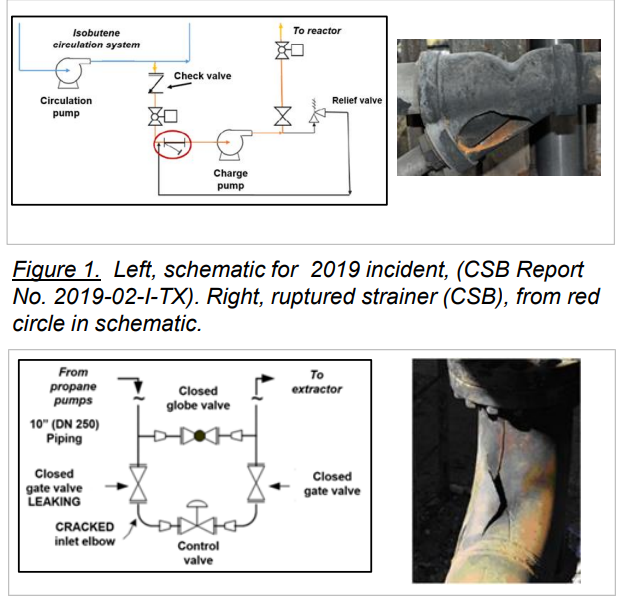

In April 2019, at a facility producing specialty chemicals, a piping section filled with liquid isobutene was closed off. As its temperature slowly increased, a cast-iron strainer burst, leaving a hand-sized hole. The release was followed by an explosion and fire, injuring 31, one of them fatally, and causing enormous damage. See the May and July 2024 Beacons.

In February 2007, at a refinery, a section of piping cracked and released pressurized propane. That section had been out-of-service for 15 years but was still connected to active piping. The resulting fire injured four and caused huge material losses. One leaking block valve allowed small quantities of water, contained in the propane feed, to collect in a low part of the seemingly blocked-off section. Cold temperatures caused the water to freeze and split the pipe. When the ice thawed, propane escaped. (See the October 2008 Beacon)

Did you know?

- Matter normally expands when temperature rises. This is because its molecules or atoms move more and occupy more space.

- The gas phase of any material has a much larger volume than its solid or liquid phases. A gas is matter that occupies a lot of empty space. A gas can easily be compressed which reduces the empty space.

- For gases like air, a temperature increase from 32 °F (0 °C) to 523 °F (273 °C) doubles the volume. If no additional volume is available in the pipe or container, the pressure doubles.

- Liquids and solids have tightly packed molecules and atoms and even very high pressure cannot compress them much. When heated, they expand; liquids much more than solids. Pipelines in hot service have compensating expansion loops and liquids blocked-in without a gas space or relief device can rupture equipment as is shown in Figure 1.

- Water expands by nine percent on solidifying (freezing). This effect makes ice float, bursts water bottles in a freezer ‒ and it ruptured the elbow in the propane piping in Figure 2.

What can you do?

- When you notice parts of equipment that are not rigidly fixed, it may be to compensate for thermal expansion. Do not try to correct it; point it out to your supervisor.

- Do not block in hoses or pipes that are filled with liquid, if this is exposed to sunlight or heat, unless there is a relief device. This is easily overlooked during troubleshooting activities. Follow established procedures for isolating and depressurizing.

- If ambient temperatures can drop below 32°F (0°C), check that where the piping could contain water is freezeproofed. The freezing point of other materials may require freezeproofing at different temperatures.

Too hot or too cold can be a bad “break” for your equipment

Download the latest Process Safety Beacon

Source: CCPS. All rights reserved.