Process Safety Beacon: Several errors lead to a hydrogen leak & fire

A release of high-pressure hydrogen occurred at a hydrogen trailer transfer/filling facility in Santa Clara, California, on June 1, 2019.

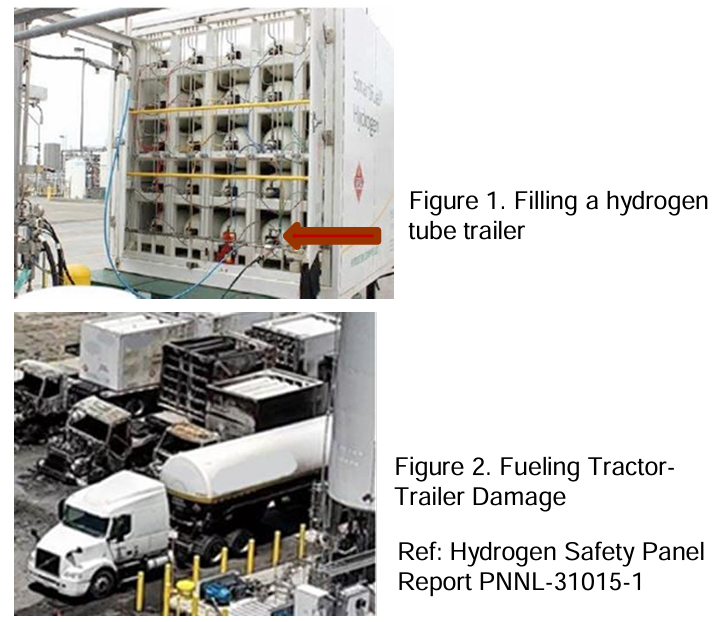

A driver and trainee were filling a tube trailer from a hydrogen tank nearby. When the trailer modules were about 95% full, the trainee noticed a hydrogen leak near the fill line manual isolation valve and informed the driver. The driver instructed the trainee to stop the filling operation. The trainee stopped the filling process for both modules but did not disconnect the trailer from the fill system piping. (Figure 1) The driver closed the manual valve (arrow) to isolate the front module from the supply, depressurized the fill manifold, and removed a piping section to repair the leak. The driver did not have the parts to complete the repair and instructed the trainee to shut off the hydrogen supply. The trainee inadvertently restarted the filling process by pressing the wrong control button. This opened pneumatic valves on the trailer allowing gaseous hydrogen to escape at a high flow rate through the disassembled piping. The hydrogen-air mixture ignited and resulted in a hydrogen-air deflagration explosion followed by a jet fire.

The fire and explosion caused piping damage (Figure 2) and activated the hydrogen temperature-pressure relief devices, adding fuel to the incident. The fire spread to other materials on adjacent vehicles. Approximately 250 kg (550lbs) of hydrogen was released during this event. There were no serious injuries.

Did you know?

- Hydrogen is the smallest molecule and can leak through very small gaps.

- The ignition energy of hydrogen is 0.02mJ. By comparison, natural gas has an ignition energy of 0.29mJ.

- Piping systems can be complex and may require a diagram and procedure to properly isolate it.

- Repairs should only be attempted when the equipment is properly isolated from the hazards and only performed by authorized personnel.

- Repairs to hazardous material piping must follow approved procedures and methods.

- Stop work authority allows employees to halt a job if they do not have the training or procedures to safely perform a task.

What can you do?

- Use the isolation or Lockout-Tagout (LOTO) procedures for the equipment. Before opening any connections, inspect the piping to confirm all valves are in the correct position

- When a leak occurs, follow the company’s leak procedure. If possible, safely isolate the leak, and notify the correct people.

- Process controls should be easily understood. If control labels are hard to understand, ask for clarification.

- Repair process equipment only if you are trained and approved.

- When working with a newer employee, provide clear instructions for the assigned tasks. It is better to show them the correct way than to only tell them.

When leaks occur, follow the procedures and ask for assistance.

Download the latest Process Safety Beacon

Source: AIChE. CCPS. All rights reserved.